The SASH (Sexual Assault and Sexual Harassment) requirements under Title 46 of the United States Code call for ship owners, ship managing operators and refurbishment shipyards to install robust security systems such as video and audio surveillance systems onboard. One way to efficiently manage this urgent task is to use Roxtec non-weld multi-cable transits.

Since November 2023, owners and operators of certain commercial vessels not carrying passengers are obliged to take action to prevent sexual harassment at sea. They must, for example, install surveillance equipment no later than two years after enactment of the Don Young Coast Guard Authorization Act of 2022, or during the next scheduled drydock. The video and audio equipment shall cover each passageway, and all the recordings shall be stored for a specified time.

Eliminate the need for welding

How can you route and seal additional cables for all those surveillance cameras and data storage servers in a quick, safe and cost-efficient manner? To help ship owners, operators and shipyards handle the intensive modernization and digitalization of vessels, which often requires additional cables and equipment, Roxtec has developed fit-for-purpose cable sealing solutions. The seals eliminate the need for hot work permit, welding and fire watch while enabling high cable density also in very limited spaces. Thereby, they even allow for cost-efficient upgrades while in operation.

Minimize the need for drilling

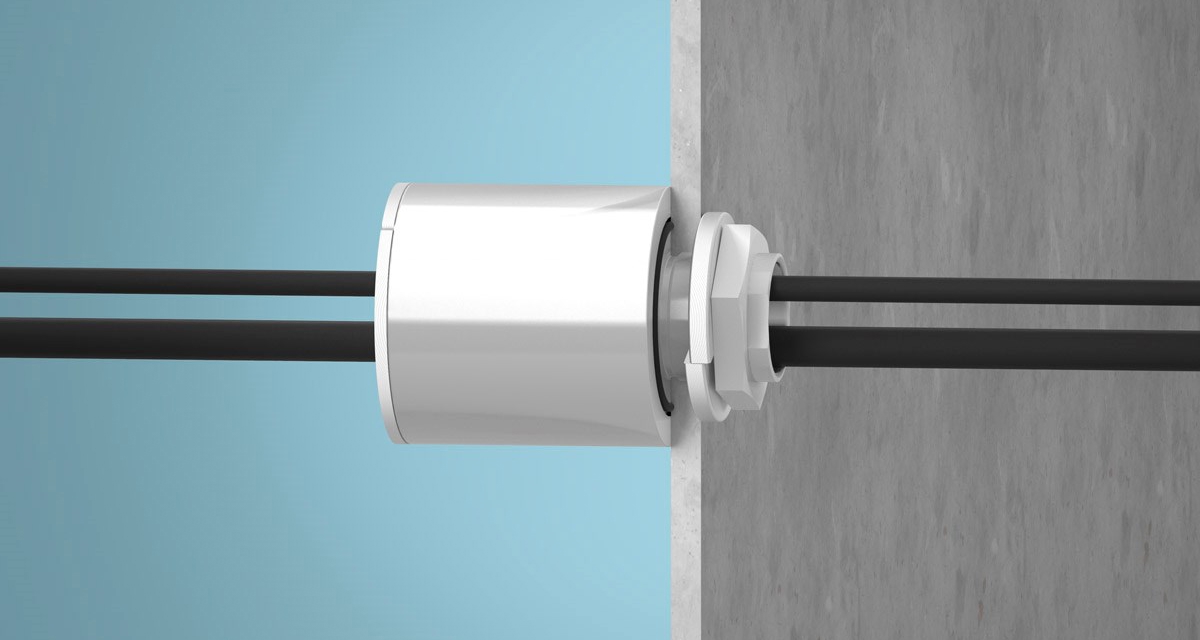

One example is the Roxtec SLA sealing solution, consisting of a seal and an adaption sleeve. It is designed to simplify the installation process and enable addition of cables without welding. The installing electrician simply drills a hole in the structure using a hole saw. The sleeve is threaded, mechanically attached with a counter nut and designed to fit in standard hole saw openings.

Reduce installation time and costs

This means there is no need for disrupting operations just to be able to open existing cable transits and add the new cables. In addition, the sealing solution is easily adaptable to cables of different sizes. An electrician, who has experienced the Roxtec SLA, highlighted the unique advantage in this way:

“This is the only product I am aware of that allows you to drill a round hole into a bulkhead.”

The Roxtec SLA solution is approved by all IACS class societies for steel and aluminum bulkheads and decks for A-Class fire barriers. It has a 2.5 bar water-tight rating and can be used all over a ship.

Roxtec representatives are at your service. We can help you find the right solution for your needs.

|

Precisions regarding the type of vessel |