A train is a chain and never stronger than its weakest link. Therefore, it is mandatory to consider each selection of components. A typical example is the choice of cable, pipe and conduit penetration seals.

Here are three things to reflect on before choosing sealing solutions for your next rail vehicle:

1. Proven protection

Make sure the seals you decide to use have proven fire break-through performance. The supplier must be able to provide test reports in line with industry standards. This should include positive results from flammability, smoke density and toxicity tests and official documents confirming that the seals meet HL3 requirements. In addition to fire protection performance, a penetration seal worthy of being present in your perfect locomotive, high-speed train or commuter train should ensure protection against dust, air-shock and vibration. You cannot design or produce the complete train without first class components.

2. Optimized efficiency

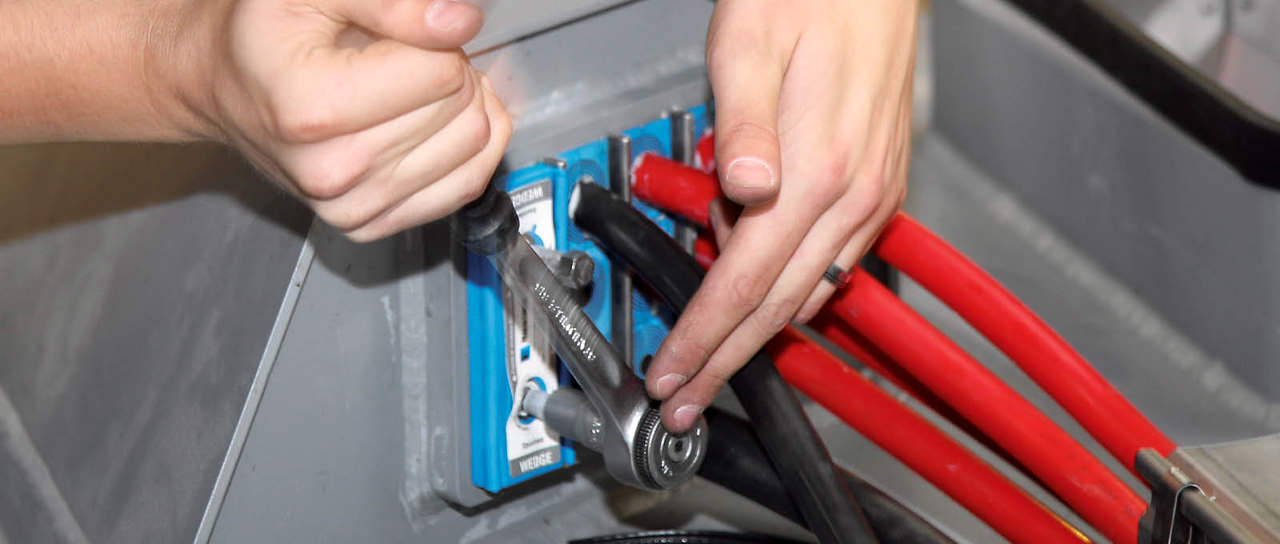

Look for sealing solutions that simplify the work of designers, manufacturers and maintenance teams without compromising safety. The seals should be lightweight, space efficient, and quick and easy to install – in other words purpose-made by sealing specialists who really know the rolling stock industry. In order to ensure cost-efficiency as well as preparedness for future needs and upgrades, your seals should be openable and if possible provide spare capacity for additional cables, pipes and conduits.

3. Uniform applicability

After selecting cost-efficient and user-friendly high quality seals, you should implement them as the standard solution for your entire train platform. Therefore, you should look for a sealing system that covers everything from undercarriage to rooftop applications.

Naturally, it must be able to help you seal conduit penetrations in walls and floors. It should simplify how you manage dust-exposed hydraulic, pneumatic and water pipes and conduits to and from control boxes under the train, as well as to efficiently keep power cables in sub-areas in place. The system should also let you decide whether you want to use bolts or welding to attach the seal to the train structure. Finally, you must be able to deploy the same sealing system to protect openings for cables serving electrical equipment, antennas, pantographs, or air-conditioning systems via the rooftop.

Does it seem hard to find the perfect seal for your perfect train? Do not despair. There is a solution.