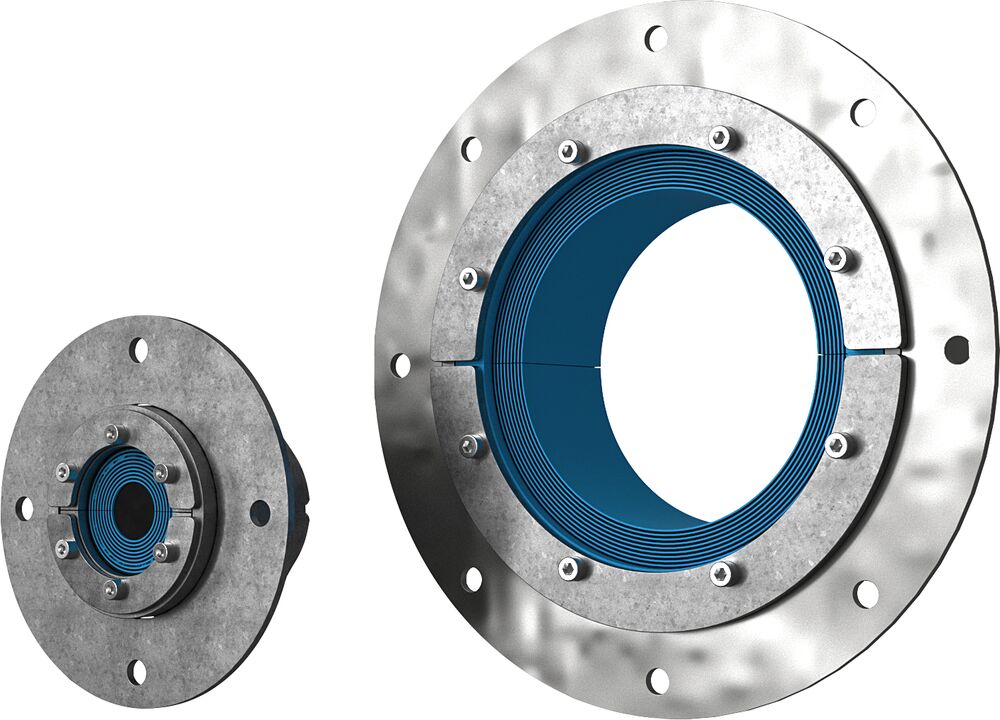

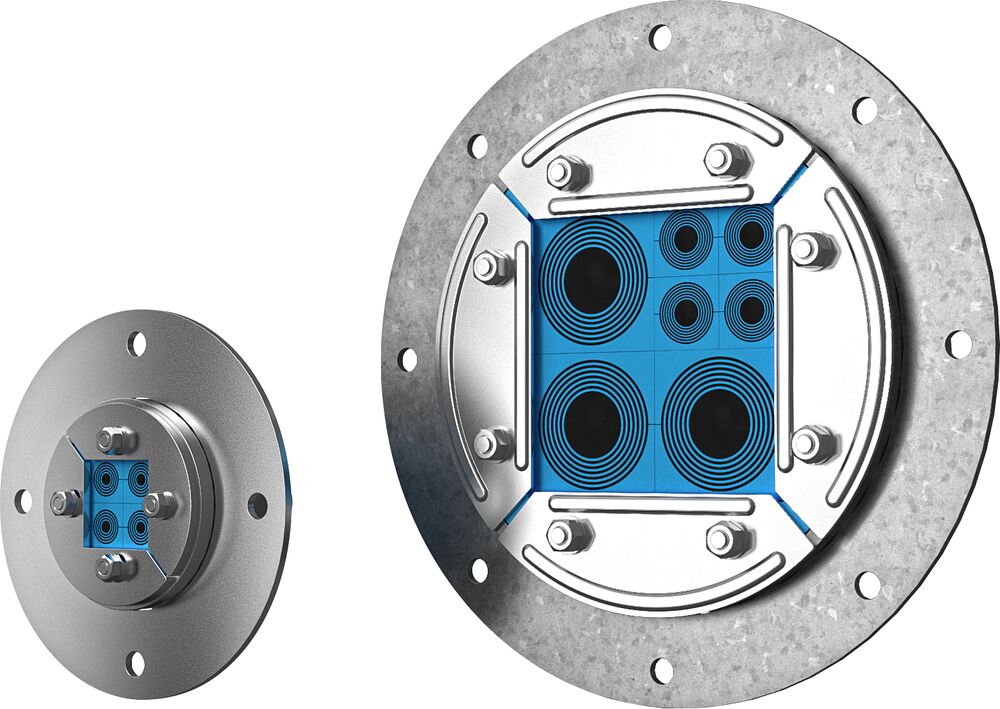

The Roxtec sealing system helps you ensure the integrity of your packaged and containerized equipment. Elevate your equipment's reliability and safety with Roxtec seals.

Why use Roxtec?

- Watertight

- Gas-tight

- Dust-tight

- Bonding and grounding

- Ex solutions

- EMC

- Cable retention

- Noise cancellation

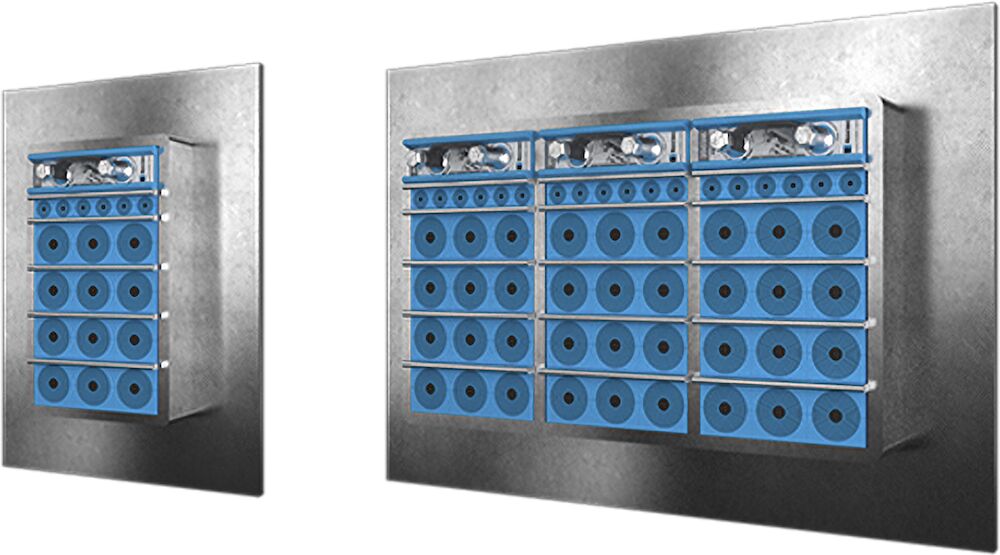

Superior simplicity

- One cut-out for dozens of preterminated cables

- Built-in spare capacity for future cable and pipes

- Space and weight saving

- Increasing service life of the equipment

- Noise cancellation

- Vibration damping