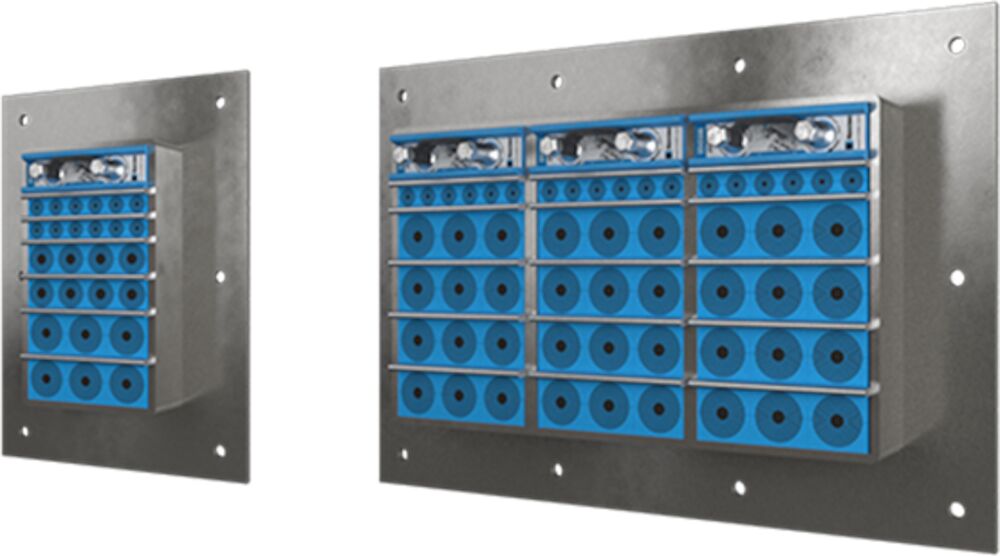

Roxtec is your area efficient one-source solution when multiple cables or pipes of different types need to penetrate any type of wall or floor and the structure must meet certain safety ratings. Keep your site dry and protect equipment from humidity and rodents. Roxtec sealing solutions enable a reliable installation for power back-up which is crucial for continuous operation. Protect your sensitive equipment such as DAS, distributed antenna systems, with our safe and certified seals.

Why use Roxtec?

- Watertight

- Dust-tight

- Airtight

- Firestop

- Pest and rodent barrier

Superior simplicity

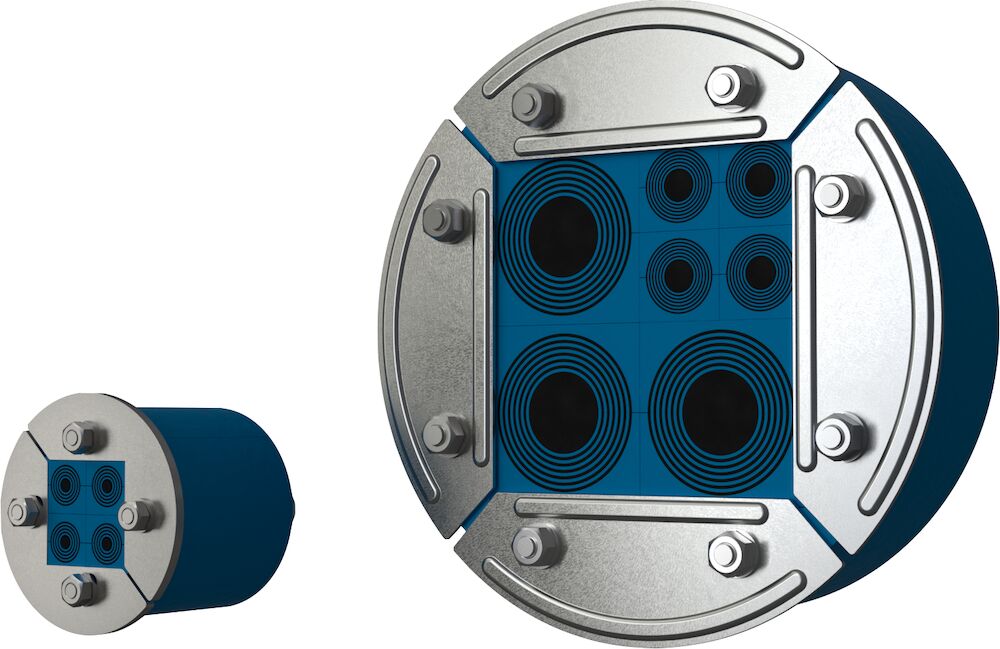

- Easy and safe installation

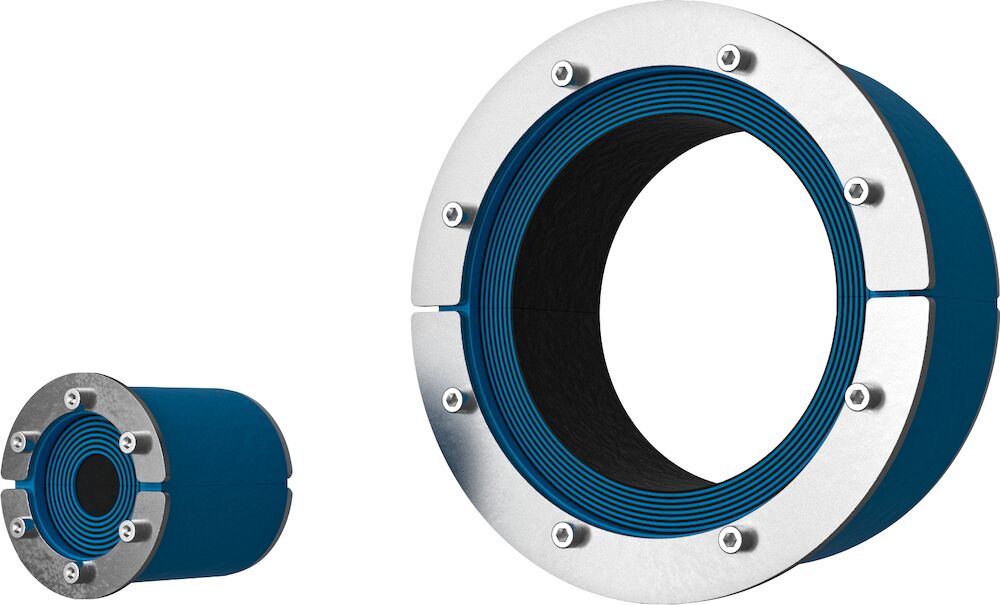

- Flexibility for cables and pipes of different sizes

- Built-in spare capacity for upgrades and retrofit

- Customized solutions for specific requirements

- One opening for dozens of cables, pipes and conduits