Molde Produksjonssenter has specialized in building advanced cranes for offshore and dockside applications. They use Roxtec transits when building diesel hydraulic light-weight cranes for operational lifting on offshore platforms.

Hydralift Molde Crane is responsible for the basic design and Molde Produksjonssenter adds to the construction through their long experience of building high quality systems and of choosing materials.

Changed to Roxtec

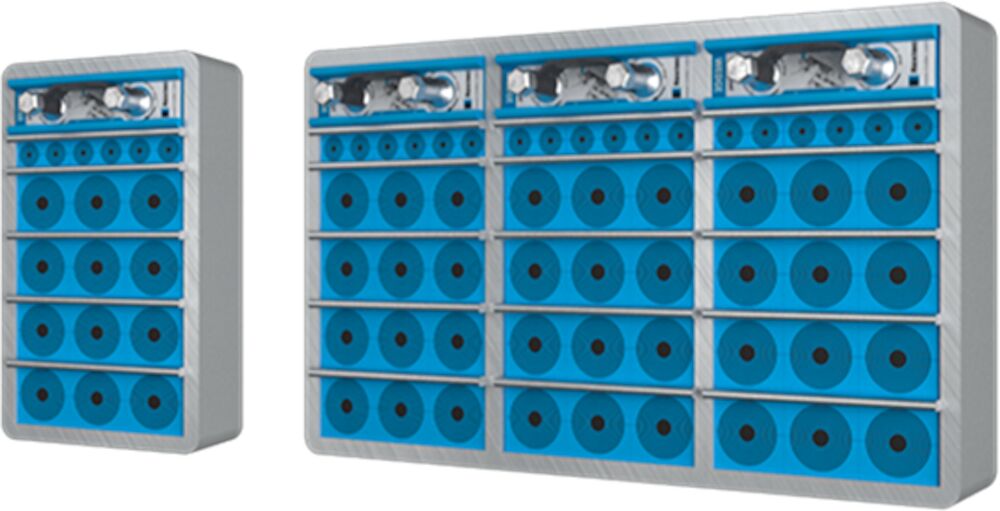

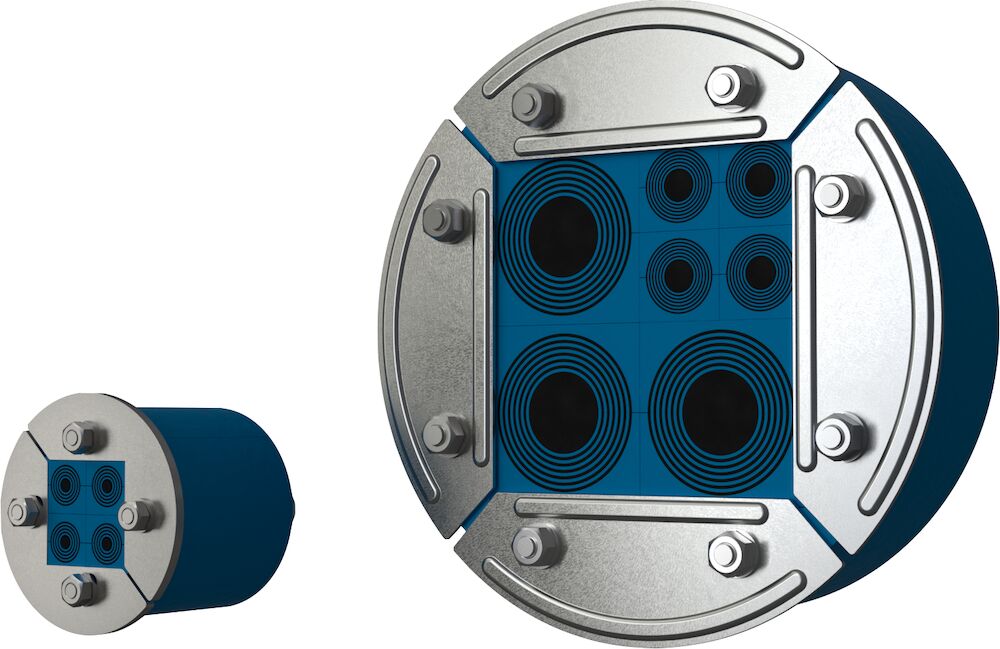

Before selecting Roxtec transits, they used stainless steel plates with traditional glands. Now Roxtec transits are used through the barrier wall of the machine house, on the outside, under and on top of the unit.

"We particularly like the Roxtec solution because it reduces vibrations at the same time as it is a cable and pipe penetration seal," says Odd Rödahl, foreman of the hydraulics department at Molde Produksjonssenter.

Quick supply

The conglomerate in Molde has the capacity to build cranes to customers' requirements and relevant rules and regulations. It is also able to produce cost-effective design and comprehensive crane control systems.

"It takes us five to six months to build a complete crane, but still, when we need Roxtec products it is overnight," says Jan Olaf Roaldset, procurement manager at Molde Produksjonssenter.

Roxtec seals reduce vibrations.

Why use Roxtec?

- Certified protection

- Vibration damping

- Quick support

- Flexible for any cable or pipe

- Seals designed for the marine environment

Project facts

Project description

Build of offshore platform diesel hydraulic crane in Molde, Norway

Builder

Molde Produksjonssenter A/S

Designer

Hydralift Molde Crane

Applications

Sealing of hydraulic hoses and pipes as well as electrical cables routed to and from the machinery house and driver's cabin

Requirements

Zone Classification: Safe area with boom in Zone 1

Roxtec products

These sealing solutions were used in the project: