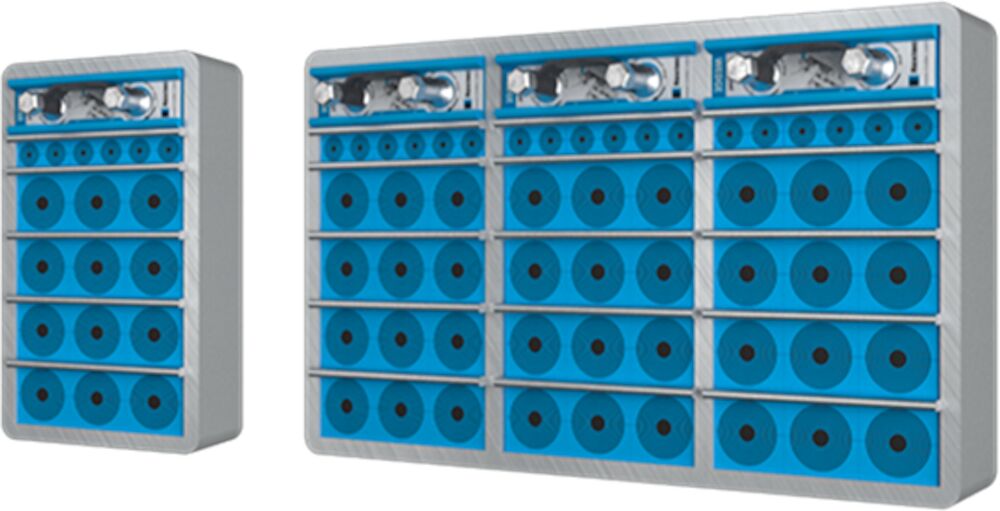

Roxtec's Ex certified cable entry solutions for drill drives, including draw works and VFD control panels, are quick and easy to use and install. Use our transits to ensure certified protection in harsh environments.

Why use Roxtec?

- Explosion protection

- Weather-proof

- Firestop

- EMI protection

- Corrosion resistant

Superior simplicity

- One cut-out for dozens of pre-terminated cables

- Flexibility for cables and pipes of different sizes

- Built-in spare capacity for upgrades and retrofits