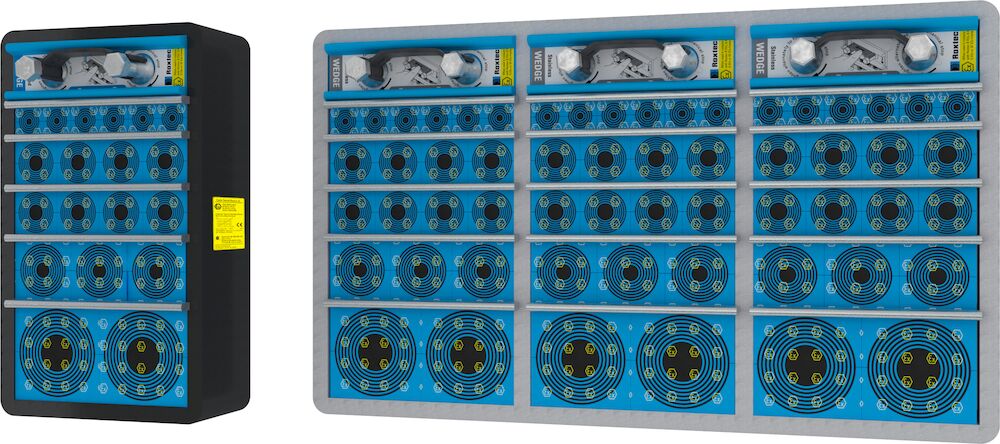

Rockwell Automation in Singapore decided to use Roxtec multi-cable transits instead of traditional cable glands when integrating ICSS, Integrated Control and Safety Systems, on FPSO vessels P80, P82, and P83. Roxtec cabinet seals were an ideal alternative, providing quick and easy installation.

The ICSS panels demand a significant quantity of cables. Using cable glands would require Rockwell Automation to pre-punch numerous holes on the gland plate, leading to extended installation time. This posed a challenge as they required a solution that could handle the complex cabling requirements without compromising on efficiency or reliability. Roxtec responded to the inquiry, engaging in technical clarifications to identify the best-fit solution.

Exceptionally swift support

Within a day, Roxtec provided all necessary documentation, including project references and certificates. This prompt response set Roxtec apart from alternative brands.

“Roxtec’s global reputation and its comprehensive and updated certification helps to seal the acceptance from customer," says Mr. Thomas Tang, Project Manager at Sensia Singapore. "Surprisingly, some competitors cannot even produce a valid ISO certificate and IECEx certificate.”

Numerous long-term benefits

Roxtec MCTs, multi-cable transits, offer several benefits for Rockwell Automation. They allow for easy customization and installation according to on-site conditions, minimizing the need for extensive modifications to existing panels. The flexible seals enable expansion of the panel designs without significant physical impact, ensuring scalability for future requirements. Roxtec’s efficient processes facilitated a quick turnaround, minimizing downtime and ensuring project timelines were met.

Partnership for mutual success

Rockwell Automation highlights Roxtec's professionalism in addressing technical queries:

“Roxtec is technically competent,” says a strategic buyer at Rockwell Automation (Sensia). “Initial technical clarification was attended promptly and professionally to address the areas of concern. No doubt on the product quality and certifications which were quickly accepted by the client."

Roxtec’s customer service was proactive, ensuring the fulfilment of both initial and subsequent orders within a tight timeframe. Both first and second batch orders were turned around within six weeks. According to Rockwell Automation, the partnership facilitated project execution and laid the foundation for long-term collaboration and mutual success.

Roxtec’s global reputation and its comprehensive and updated certification helps to seal the acceptance from customer.

Why use Roxtec?

- Certified protection (ISO, ABS, IECEx)

- Ease of installation

- Support from technical expertise

- Tailored solutions for specific needs

- Assistance throughout the project

Project facts

Project description

Integration of ICSS, Integrated Control and Safety Systems, on FPSO vessels in Singapore

Involved companies

Rockwell Automation – design, engineering and installation

Applications

Sealing of cables entering control cabinets

Sealing requirements

• IP rated

• Ex rated

Roxtec products

Roxtec S Ex transits

Roxtec products

Roxtec S Ex transit

Ex rated transit for welding to the structure.

For welding into precise apertures in hazardous locations