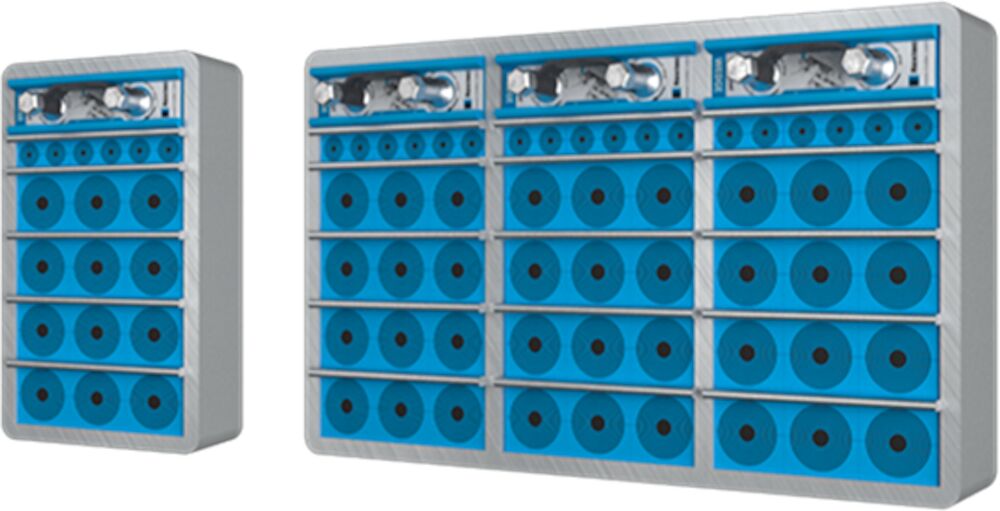

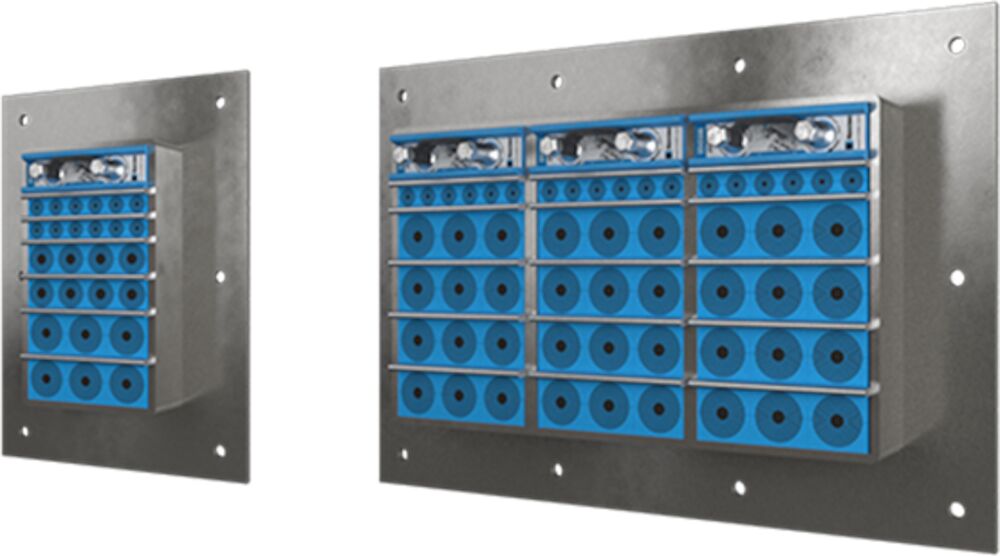

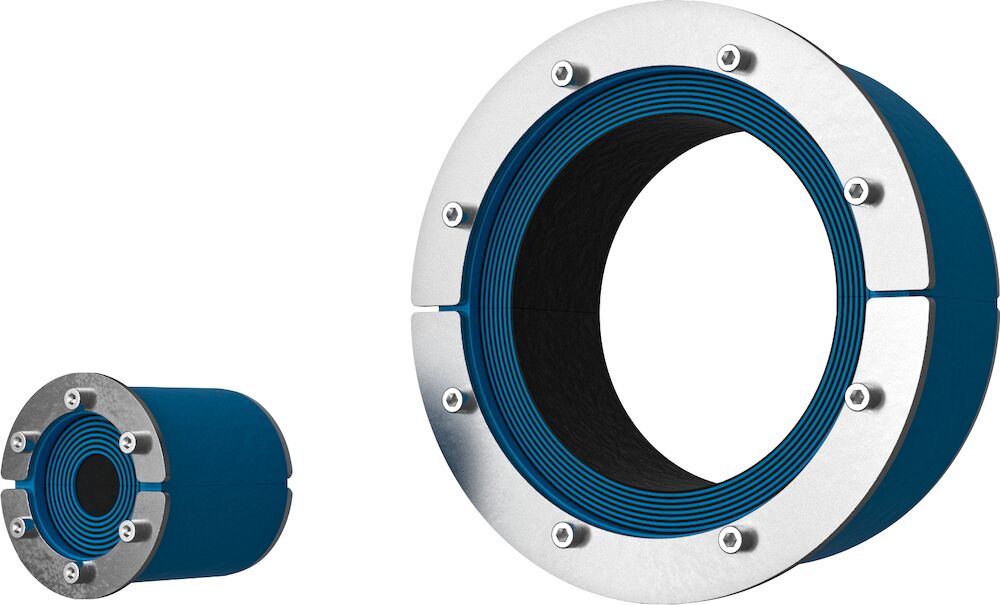

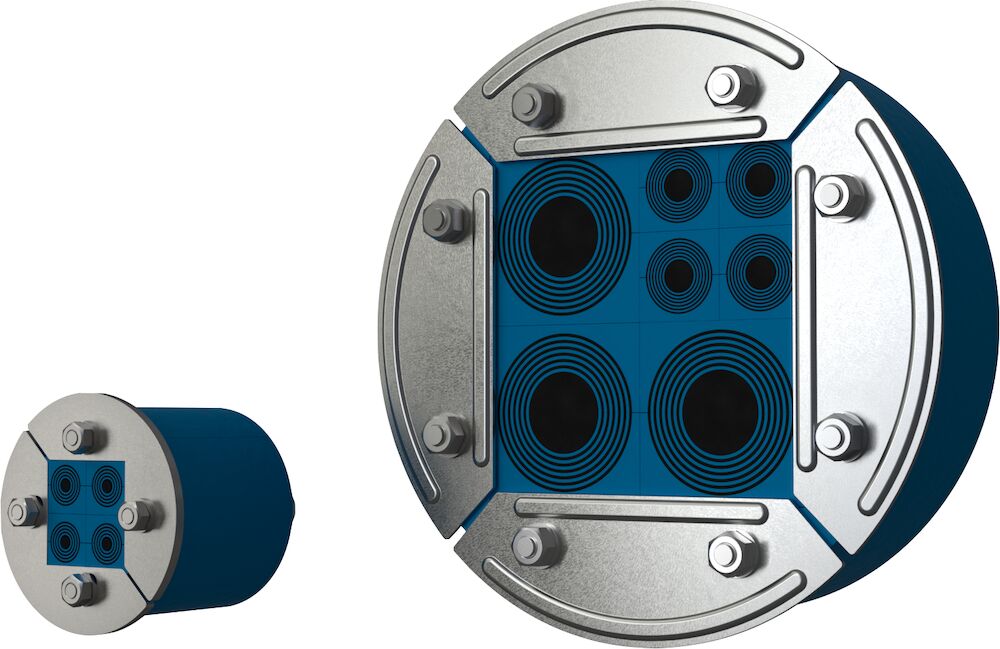

We provide design support and work together with wind turbine component suppliers in order to find the best sealing solutions for all requirements in every application. Our seals cover challenges such as weather protection, cable management, cable torsion/retention and various levels of EMC protection.

Why use Roxtec?

- Watertight

- Bonding and grounding

- EMC protection

- Vibration damping

- Cable retention and cable management

- Quick and easy installation

- Cost-efficient solution for component supplier

Superior simplicity

- Flexibility for cables and pipes of different sizes

- Easy design with the online tool Roxtec Transit Designer™