Carometec A/S uses Roxtec cable seals in their stainless steel touch panel enclosures for the food industry.

Carometec needed a dust-tight and watertight quality solution meeting the high demands on hygiene which require daily high temperature, high pressure hosing. They also wanted to be able to change and add cables with ease.

Proven sealing solution

"For more than three years these touch panels have been pressure hosed on a daily basis with water and cleaning agent at a temperature of 80°C and at a pressure in excess of 100 bar. We have never experienced problems due to the ingress of water or moisture," says CEO Henrik Andersen of Carometec.

Very high demands

Carometec has produced a touch panel contained in a stainless steel enclosure for use in applications including slaughterhouses at the dirtiest part of the slaughter line. There are stringent hygiene requirements as it is a must to kill all bacteria.

Flexible for maintenance

R&D manager Thomas Lauridsen explains the challenge posed in getting the electrical connections into the rugged enclosure:

"We had to find a solution that was completely dust- and watertight yet which gave us the possibility of replacing or adding new cables, preferably without having to remove the panel from the slaughter line. With Roxtec cable seals we found such a solution and we now use this as an integral part of the enclosure."

The panel enclosures with Roxtec seals have been approved to EN 60529 (IP 69K).

We had to find a solution that was completely dust- and watertight.

Why use Roxtec?

- Certified protection

- Pressure resistance

- User-friendliness

- Openable solutions

- Built-in spare capacity

Project facts

Project description

Production of touch panels for the food industry in Herlev, Denmark

Equipment manufacturer

Carometec A/S

Applications

Sealing of cable entries in touch panel enclosures

Sealing requirements

Dust-tight and watertight

Roxtec products

These sealing solutions were used in the project:

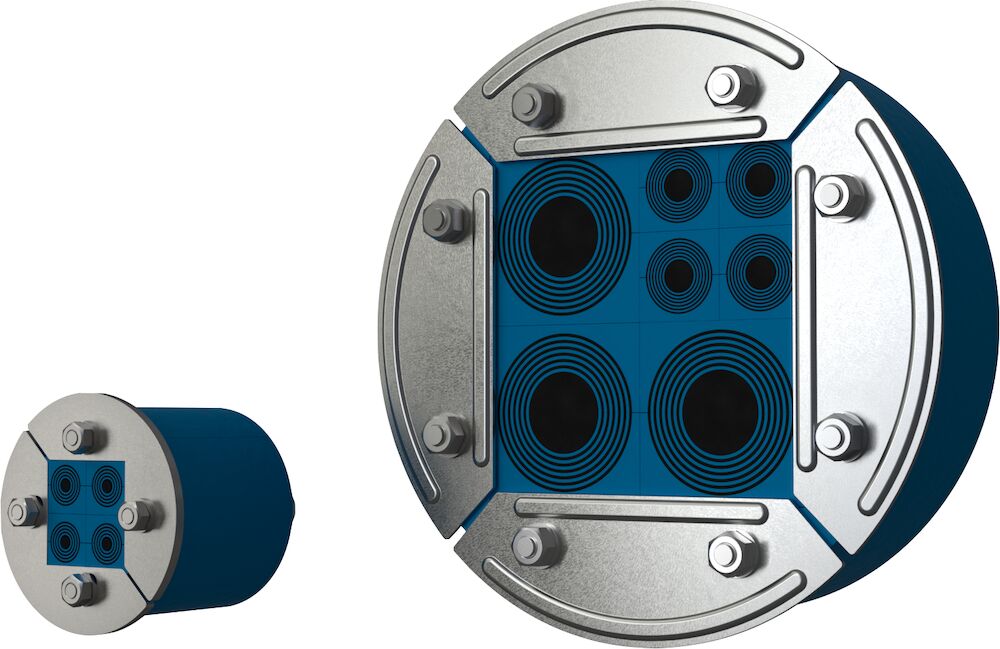

Roxtec R transit

Round transit for sealing around multiple cables and pipes in a limited area.

For installation in existing sleeves