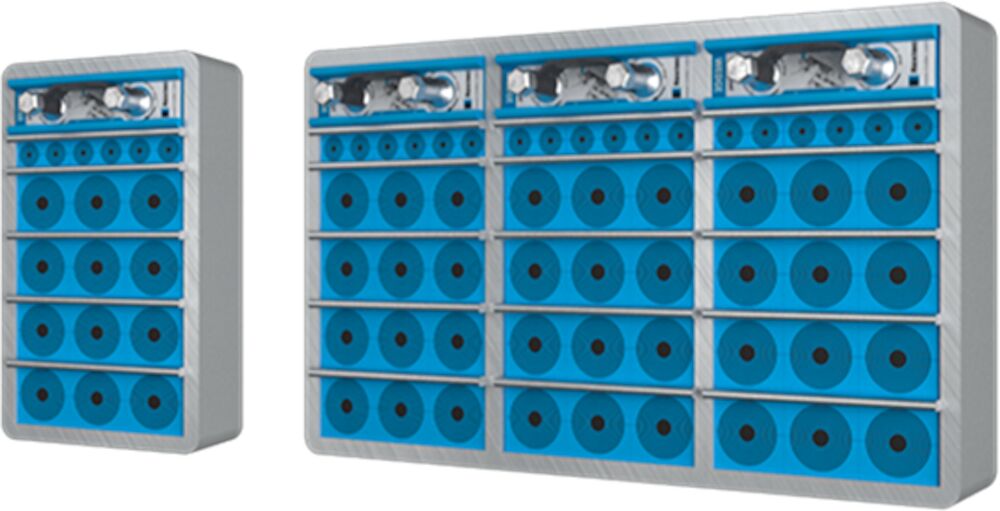

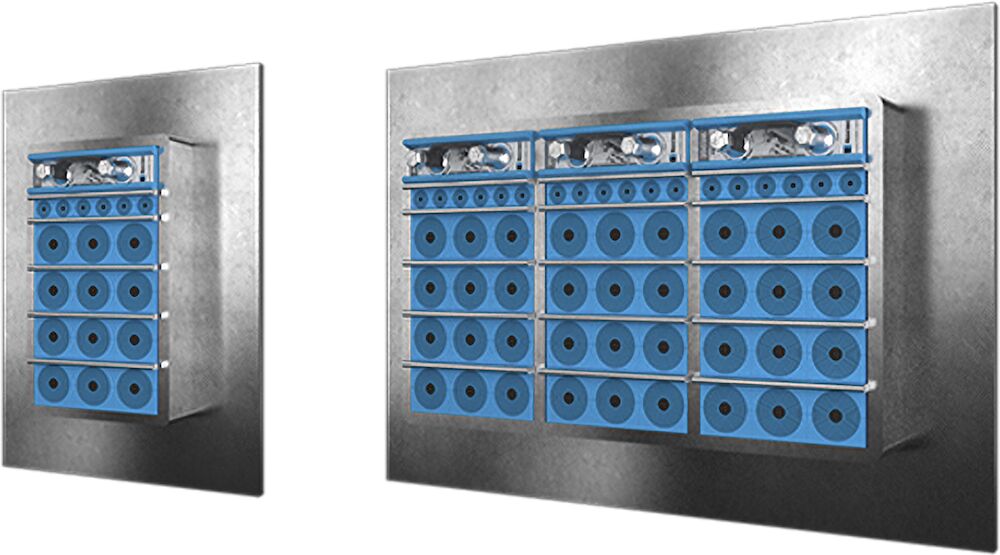

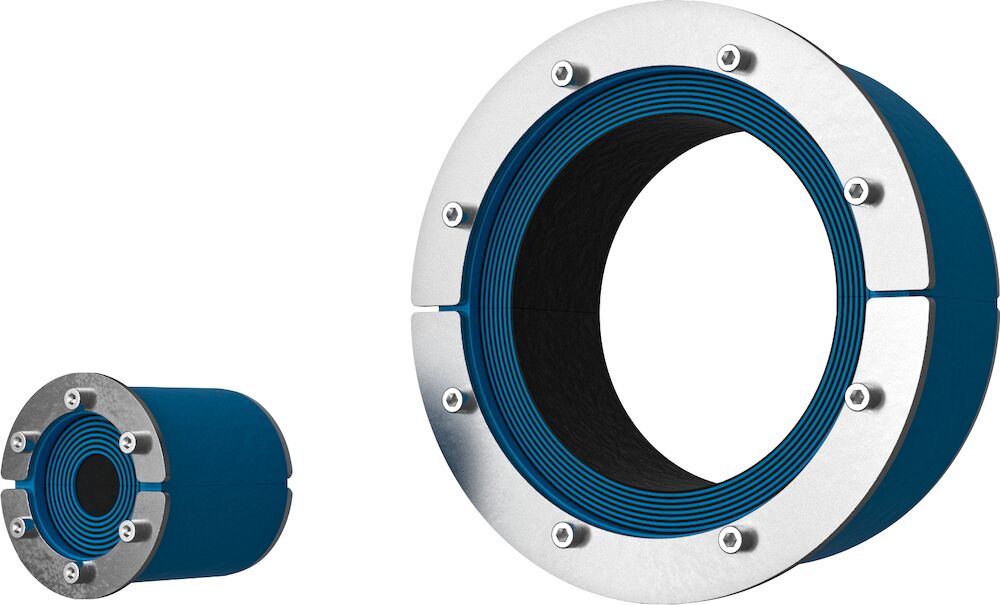

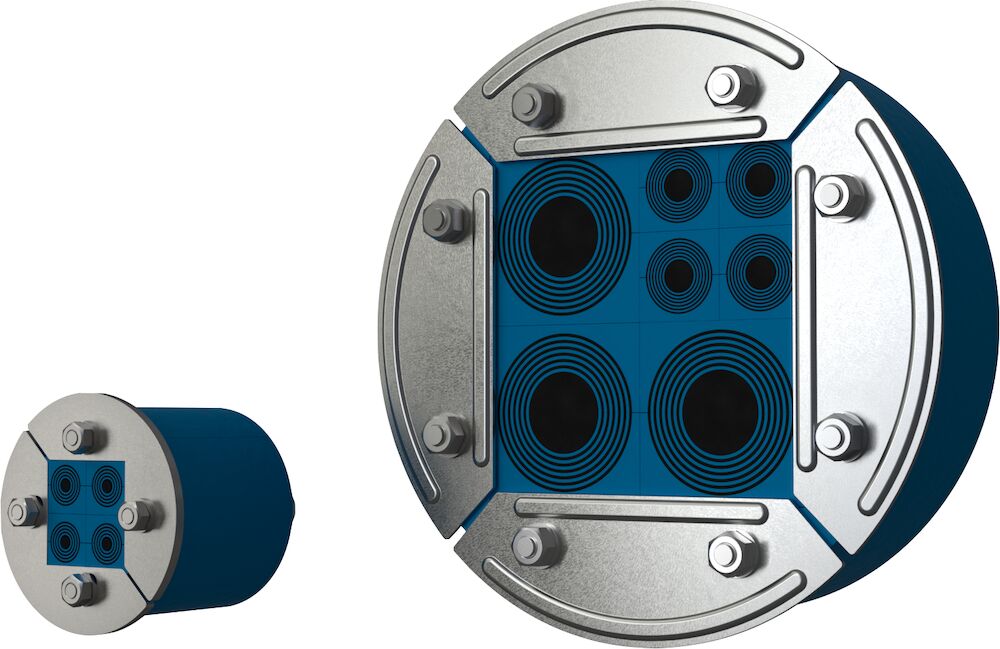

Roxtec cable and pipe sealing solutions provide the flexibility you need onsite to handle an unexpected number of armored cables and pipes of different diameters. Use the transits in walls, floors and equipment in demanding outdoor environments.

Why use Roxtec?

- Watertight

- Firestop

- Corrosion resistant

- Explosion protection

Superior simplicity

- One opening for dozens of cables and pipes

- Flexibility for cables and pipes of different sizes

- Built-in spare capacity for upgrades and retrofits

- EMC solutions for bonding and grounding