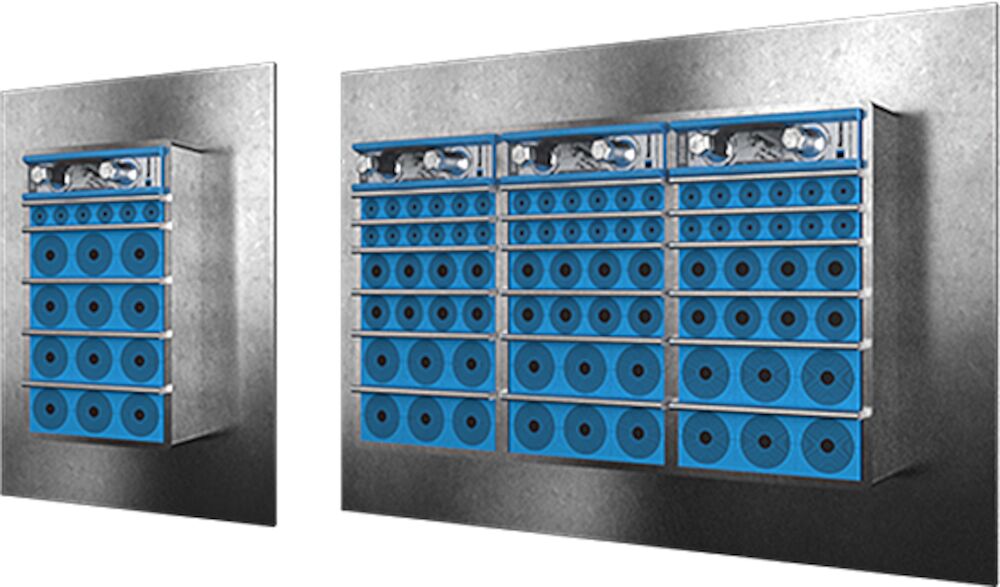

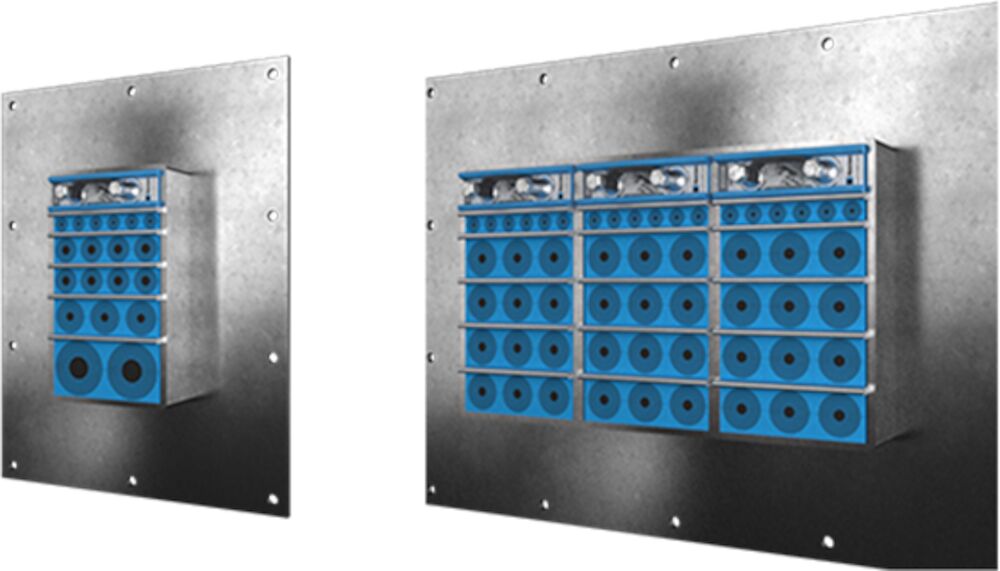

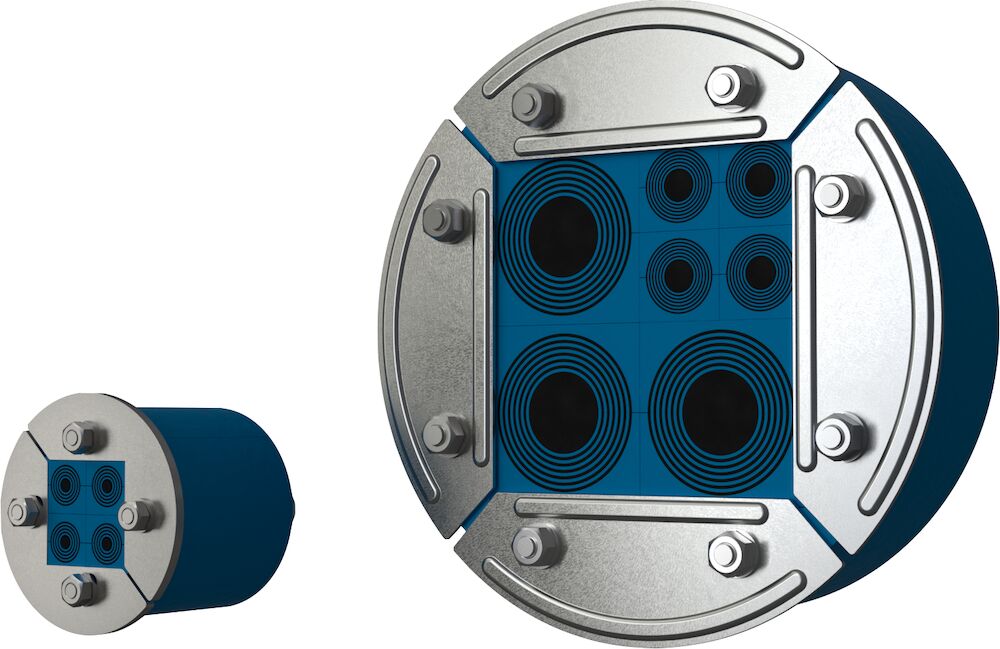

Roxtec seals meet flammability, smoke emission and toxicity (FST) requirements for technical rooms, substations, control rooms, gas detection systems and emergency phone systems in rail and service tunnels. Use our solutions for new construction projects as well as for expansion and upgrade projects.

Why use Roxtec?

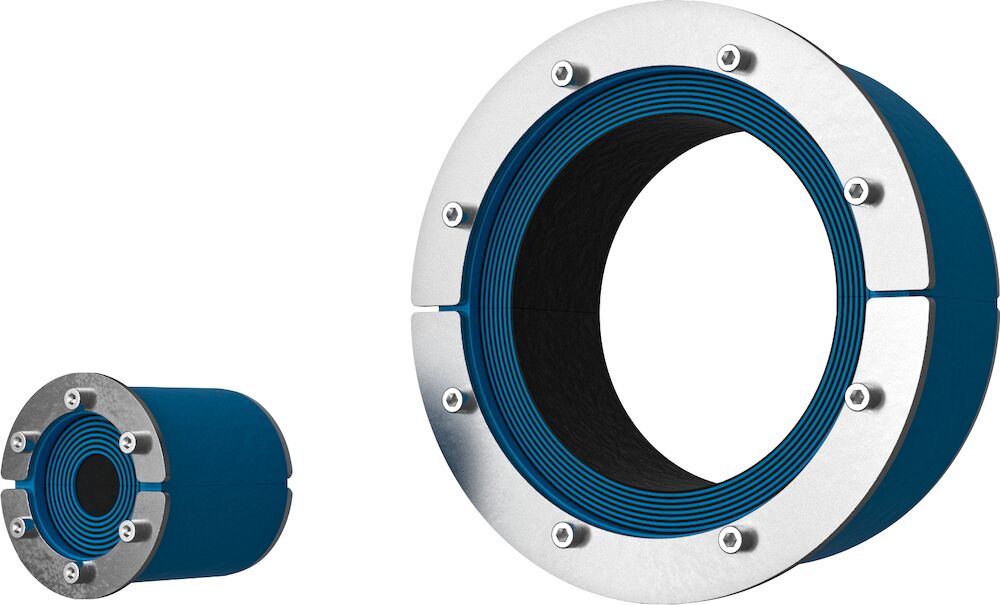

- Watertight

- Firestop

- Air-shock protection

- Pest and rodent barrier

- Flammability, smoke emission and toxicity (FST) protection

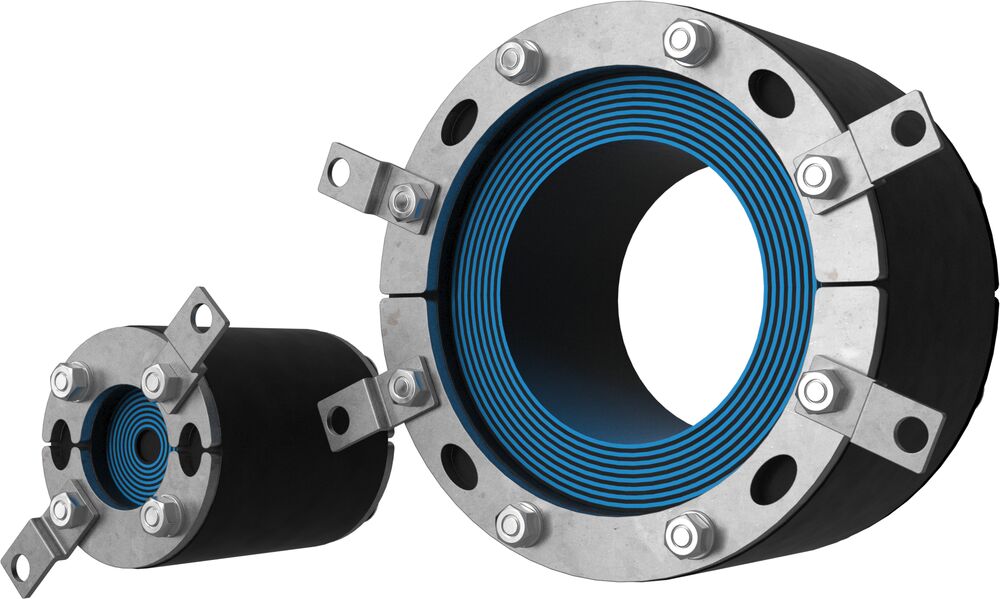

Superior simplicity

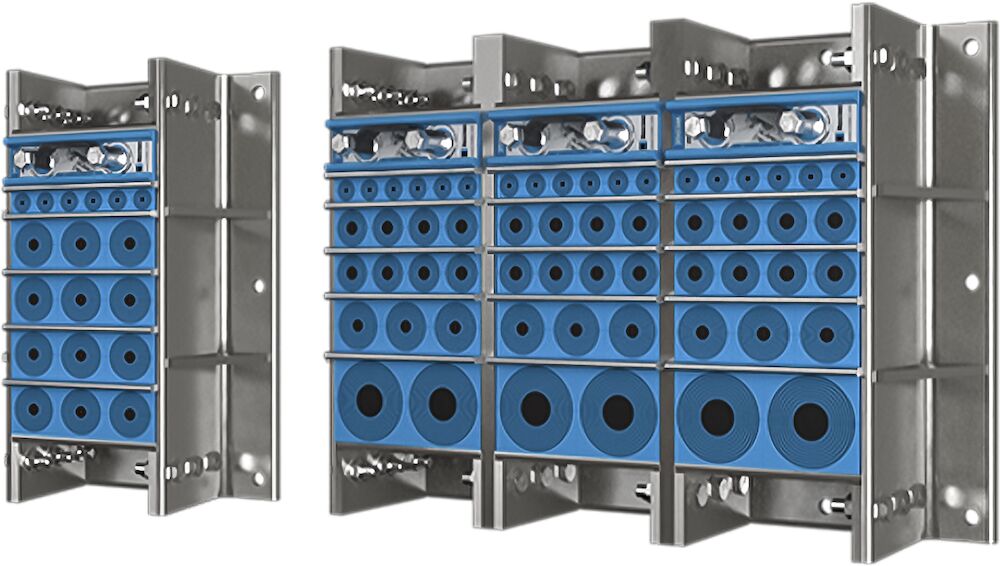

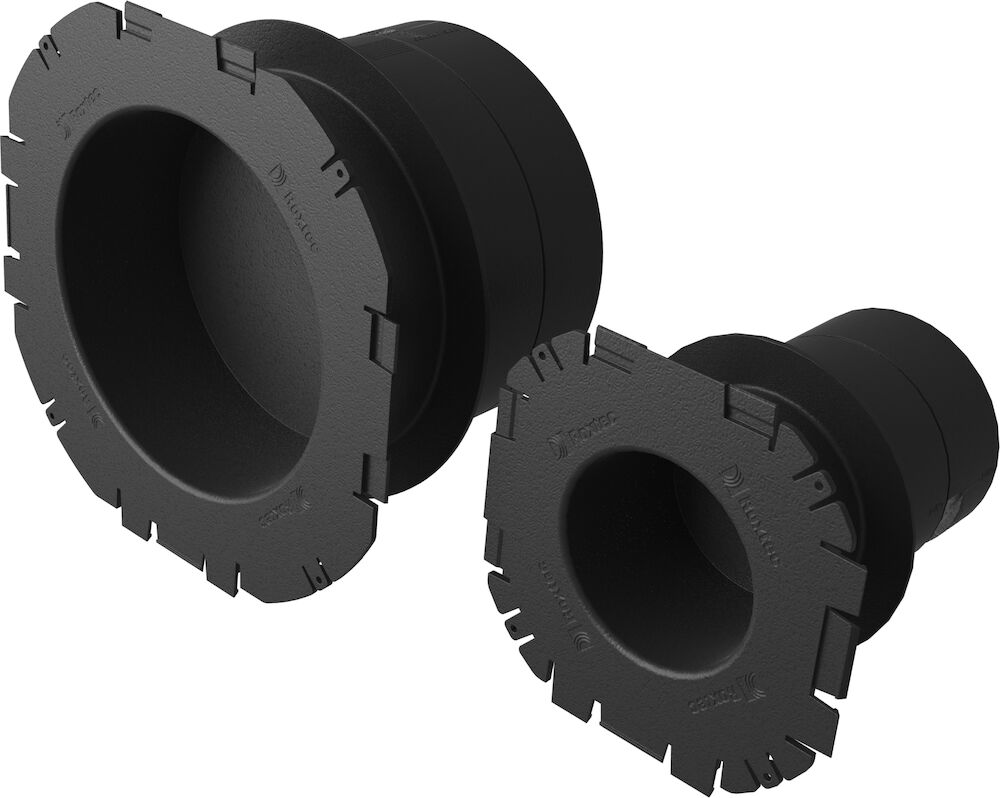

- Easy and safe installation

- Solutions designed for underground environments

- Built-in spare capacity for last-minute changes