High-pressure technology specialist Hiperbaric was looking for Ex rated sealing solutions when designing their new modular and mobile green hydrogen compressors. They chose two types of seals from Roxtec.

“Roxtec is our partner for sealing multi-cable and pneumatic tube penetrations inside the hydrogen compressors,” says Luis Ángel Ramos, Electrical Engineering Chief of Hiperbaric. “We also get valuable technical help. Roxtec experts have checked the installed system onsite to verify everything is correct.”

Avoiding the risk of explosion

Hiperbaric is an international provider of high-pressure processing equipment based in Burgos, Spain. Among the cutting-edge technologies leaving their factory are containerized hydrogen compressors for efficient storage and supply of refueling stations. Inside each container, there is an Ex zone 2 classified area that must be properly separated from the next compartment. Therefore, they need tight and Ex rated cable and pipe transits to make sure the explosive hydrogen gas is safely kept where it should be.

Flexibility enables modularity

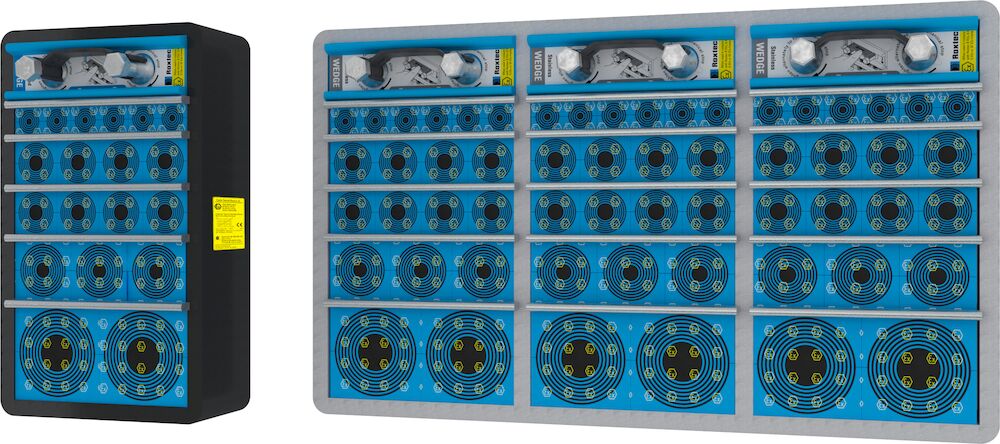

Hiperbaric selected Roxtec for several reasons. Roxtec is recognized as world leader in modular-based sealing solutions for cable and pipe transits, and the technical solutions were adequate, flexible, and enabled scalability. In addition, Roxtec seals require minimum maintenance while offering built-in spare capacity. Hiperbaric is using Roxtec S Ex transits for multiple cable penetrations, and Roxtec C RS T Ex seals around single ethernet connections. In the equipment, there are mostly 5mm to 50mm thick electrical cables for sensors and actuators, whereof some armored, but there are also pneumatic tubes.

“The Roxtec S Ex solution for multiple cables of different sizes is the best way for connecting two separated areas,” says Luis Ángel Ramos. “The Roxtec C RS T Ex seals for single cables have also been an easy and efficient solution to implement as a standard for individual cable connections.”

“The best way to connect two separated areas.”

Why use Roxtec?

- Ex, fire and IP rated

- Tested for blast load

- Flexibility for cables and pipes of different sizes

- Built-in spare capacity for rapid expansion

- Ideal for cost-efficient standardization

Download the pdf-version of the Hiperbaric, Spain case.

Project facts

Project description

Manufacturing of hydrogen compressors in Burgos, Spain

Involved companies

Hiperbaric – owner, design, engineering and installations

Applications

Sealing of cables and pneumatic tubes in Ex zone II areas

Sealing requirements

Protection against the risk of explosion, Fire protection, Gas-tight, Dust-tight and Watertight.

Roxtec products

Roxtec S Ex transit

Ex rated transit for welding to the structure.

For welding into precise apertures in hazardous locations

Roxtec C RS T Ex seal

Round transit device for single cable entries.

For single cable entry