Roxtec sealing solutions ensure electrical safety in substations in the Shanghai Yangshan Deepwater Port Phase IV Project – the world’s largest and most advanced container terminal automation port.

Phase IV of the Chinese port covers 2.23 million square meters. It has a 2,350-meter shoreline and is a strategic hub for the construction of Shanghai International Shipping Center. New technologies, products and materials are used to reduce operation costs and increase efficiency. The Roxtec system is highly appreciated by owners and designers, providing protection for the port substations.

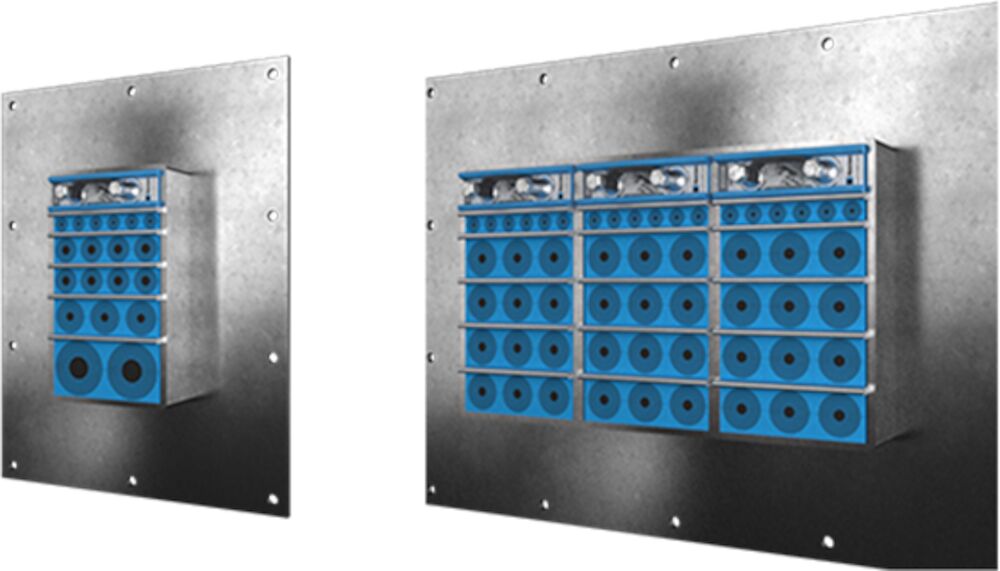

Solution for high cable density

Engineer Weizhi Chen of CCCC Third Harbor Consultants explains why the company specified Roxtec:

"Traditionally we used embedded sleeves for cable entries in substations, but a big number of sleeves in the wall affects the structure and may also lead to water flow from outside trenches into substations. We solve these problems and handle large quantities of cable by using Roxtec seals."

Preventing salty mist

The construction of the port requires stability and durability. To ensure the safety of the structures it is a must to handle the challenge caused by the salty environment of the Shengsi Islands. Small salt fog particles on the surface of electrical equipment may cause corrosion of wire, so the cable entry solution has to resist corrosion and block the salty mist from reaching equipment inside substations.

Roxtec sealing modules and Roxtec GH stainless steel frames are excellent anticorrosion materials.

Certificates of performance

"Roxtec showed us all major testing and certification from the classification society. There is no doubt Roxtec has first-class performance and protection capacity. The sealing system can fully meet the demand for electrical safety for us. It is a reassuring intelligent solution," states Weizhi Chen.

Roxtec has first-class performance and protection capacity.

Why Roxtec?

- Certified protection against multiple risks

- Online design support via Roxtec Transit Designer™

- Onsite technical consultancy throughout the project

- Customized solutions for varying opening sizes

- Built-in spare capacity for future upgrades

Projects facts

Project description

Construction of container terminal automation port in Shanghai, China

Involved companies

Shanghai Tongsheng Investment Group Co., Ltd. – owner, CCCC Third Harbor Consultants Co., Ltd. – designers, China State Construction Harbor Construction Co., Ltd. – contractors

Applications

Sealing of 10-90mm power and light-current system cables entering substations

Sealing requirements

Fire-proof, Watertight, Gas-tight, Air-tight, Salt fog safe, Rodent barrier, Corrosion resistant, Cable retention

Roxtec products

Roxtec GH FL100 transit

Transit with wide flange, for bolting onto uneven structures.

For bolting to concrete/bricks