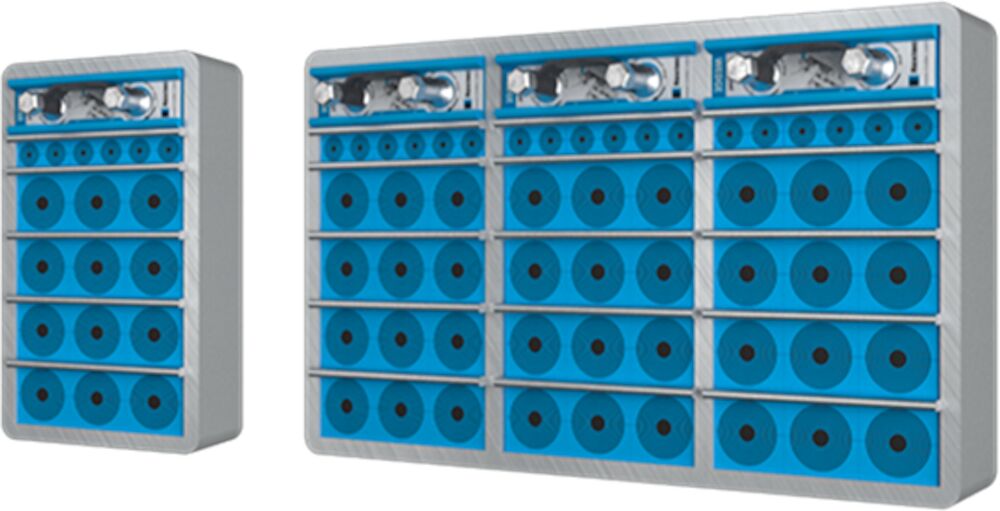

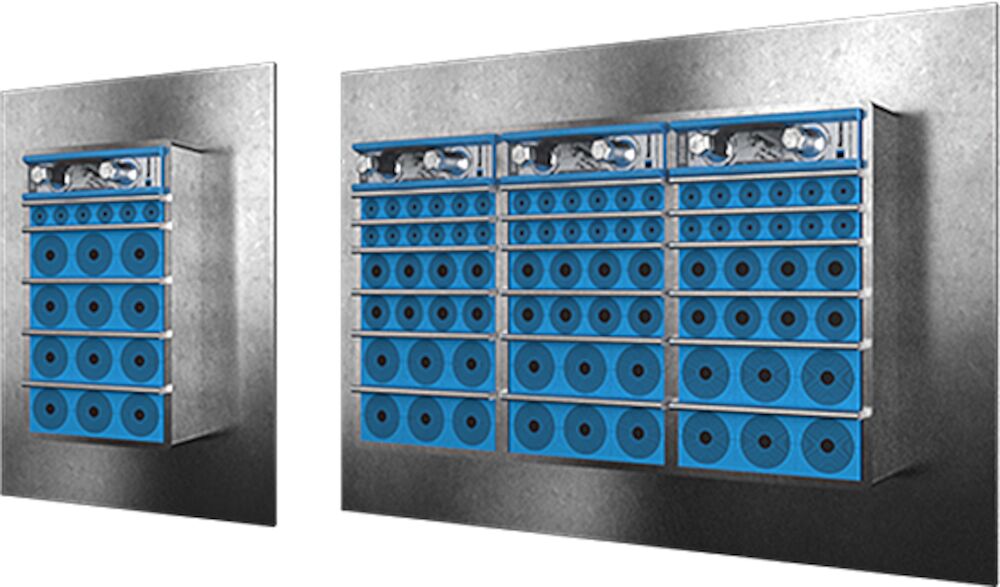

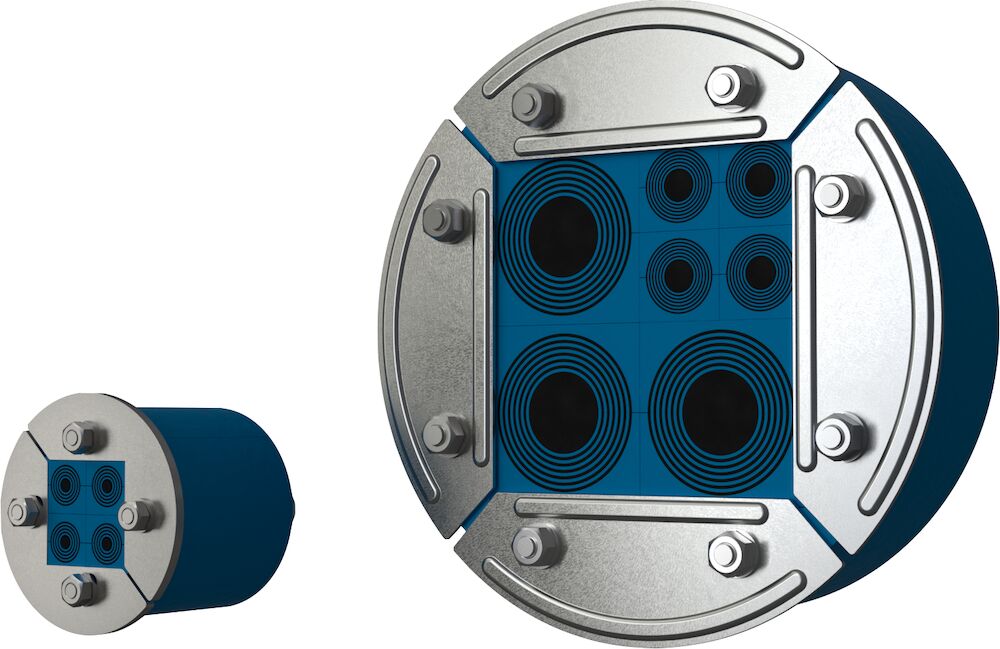

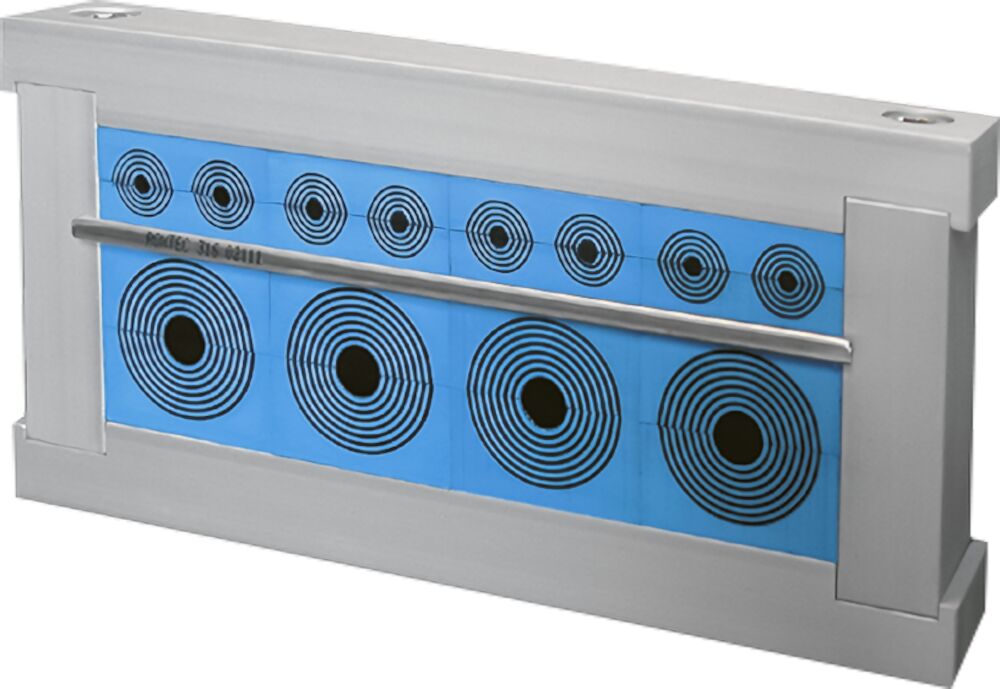

Roxtec seals are easy to install since each module is flexible and adaptable to cables, hydraulic pipes and plastic conduits of different sizes. Use our sealing solutions to maintain the integrity of the fire barrier.

Why use Roxtec?

- Fire rated

- Watertight

- Air-shock protection

Superior simplicity

- Flexibility for cables, pipes and conduits of different sizes

- Built-in spare capacity

- Welded or bolted solutions