Roxtec sealing solutions prevent downtime and allow last-minutes design changes. Combine safe and reliable operations with time-savings, cost-efficiency, and easy maintenance.

Why use Roxtec?

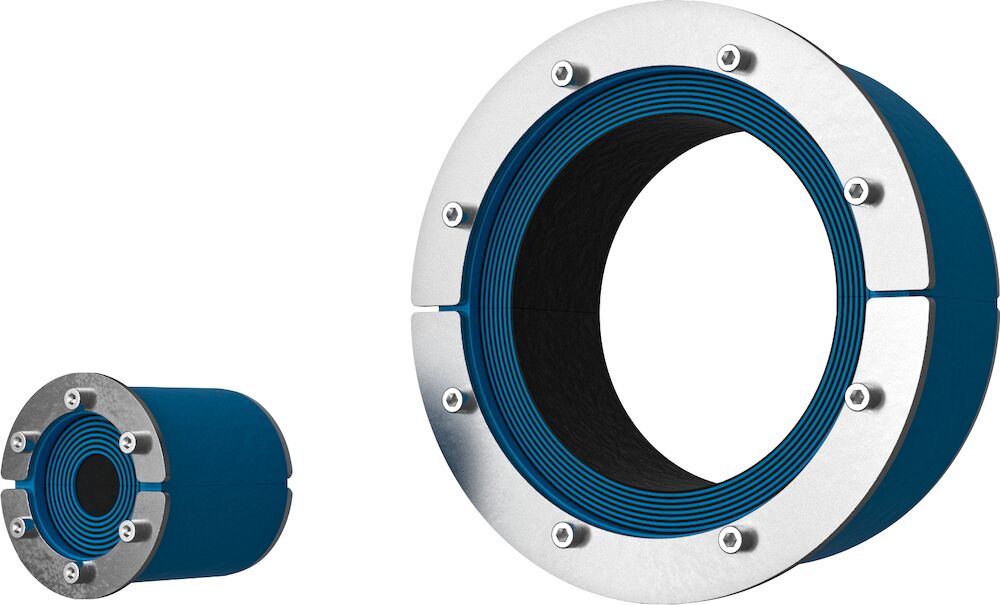

- Corrosion resistant

- Temperature-proof

- Gas-tight

- Explosion protection

- Noise reduction

- Cable retention

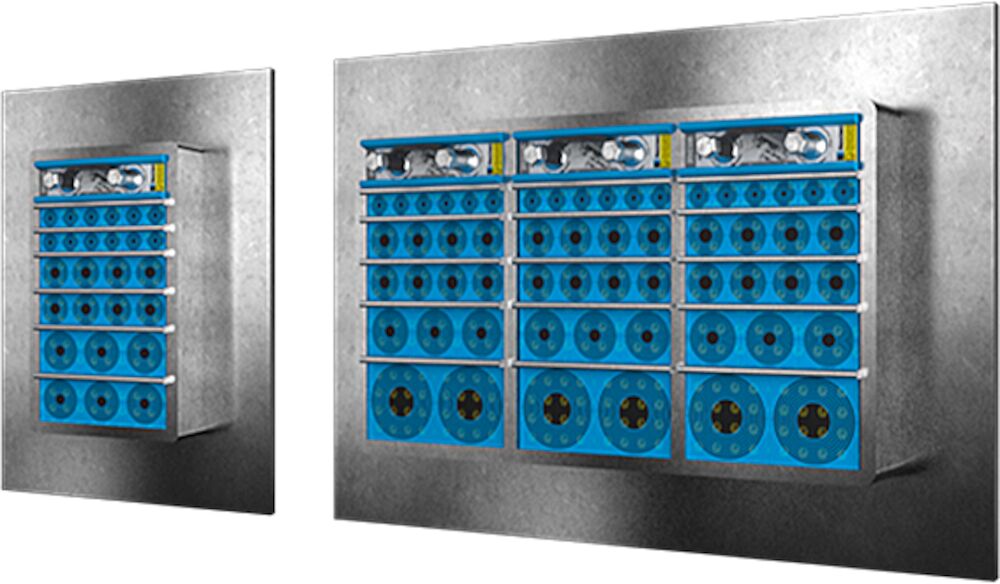

Superior simplicity

- One cut-out for dozens of pre-terminated cables

- Built-in spare capacity for future cables and pipes

- Customized solutions for specific requirements