Roxtec sealing solutions prevent water and steel process dust from entering outdoor cabinets and indoor control room containers of the Konecranes lifting equipment at SSAB’s steel works in Raahe, Finland.

The overhead traveling cranes must be operational at all times as they carry hot 25-ton steel slabs in a process resulting in 2.5 million tons per year.

"We need good cable seals to avoid dust in the electrical cabinets. The worst thing that can happen to us is a stop in the steel production," says Jarmo Manninen, responsible for crane maintenance and work planning at SSAB.

Efficient for any flat cable

Roxtec has helped SSAB and Konecranes handle a tough and frequent sealing challenge by providing sealing modules also for flat cables of many different sizes. Roxtec seals simplify maintenance logistics by reducing the need for spare parts.

"We do a lot of preventive maintenance work for safety," says Jarmo Manninen.

Konecranes started using Roxtec's area efficient seals instead of cable glands in the mid 90's. Arto Vaaraniemi, leading electrical engineer of Konecranes, explains why the successful crane provider continues to specify Roxtec seals for all cranes.

"Our customers want seals that are easy to install and that provide very good protection. When it comes to high IP ratings, Roxtec is the only seal we use."

Roxtec is a good way to seal around flat cables.

200 sizes of flat cables

200 sizes of flat cable for cranes were covered by Roxtec sealing modules!

Why use Roxtec?

- Dust-tight

- Watertight

- Blast-proof

- Easy to use and maintain

- Solutions for round and flat cables

Download the pdf version of the SSAB case.

Project facts

Project description

Industrial cranes for the SSAB steel works in Raahe, Finland

Owner, design and construction

SSAB

Design and construction

Konecranes

Applications

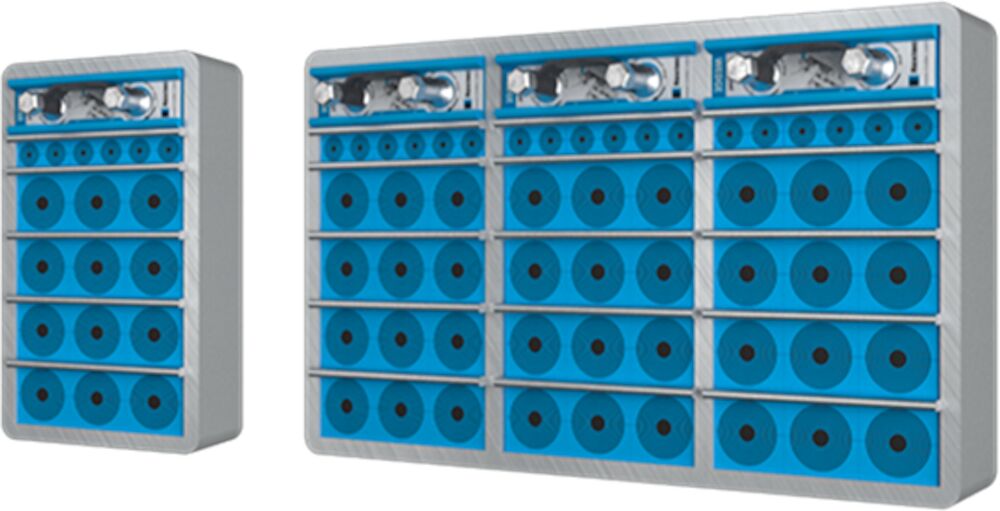

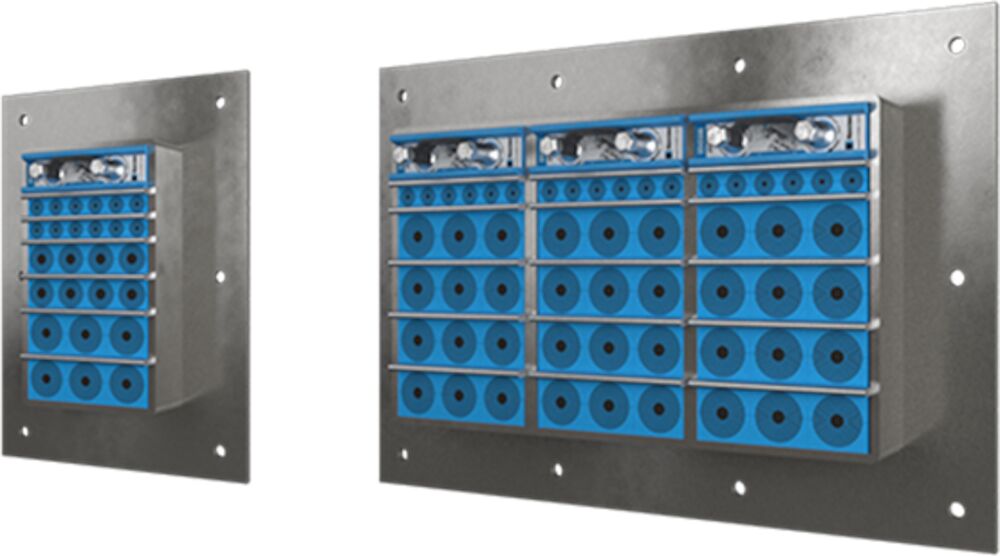

Cables penetrating control room and cabinet structures, indoors and outdoors

Sealing requirements

Dust-tight and watertight

Roxtec products

These sealing solutions were used in the project: