Did you know that there are pipe penetration seals that do not require any welding? As a designer or an installer in a shipyard, you should consider using the Roxtec RS seal for single pipes in engine room bulkheads. It enables you to deliver high quality in a quick, safe and cost-efficient manner. Also, Roxtec multi-cable transits help you handle high cable density in the engine control room.

Shipyard workers striving to seal openings for pipes and cables in the structure surrounding the engine room struggle with high varying temperatures, vibrations and lack of space. They need to meet all safety requirements regarding fire protection onboard tankers, container ships and LPG, LNG and bulk carriers, but they have neither time for welding nor place for fire insulation. It is also a challenge to route and seal all cables that enter under cabinets in the engine control room.

Innovative and certified sealing solutions

Fortunately, there are always Roxtec transits for single and multiple cables and pipes available from a warehouse nearby. Roxtec fire-resistant entry seals are tested to all relevant marine standards and certified by all major classification societies, including DNV, ABS, LR, CCS and KRS. According to several test reports, the seals withstand gas pressure, temperature cycling, shockwaves, and vibrations. They have all required material classifications for use in harsh marine environments, and for cables they do not require any fire insulation for A-0 applications and no extra insulation for A-60 applications. With the range of Roxtec pipe penetration seals, you can easily handle a variety of pipes in steel, copper, copper-nickel, composite and plastic passing through structures onboard.

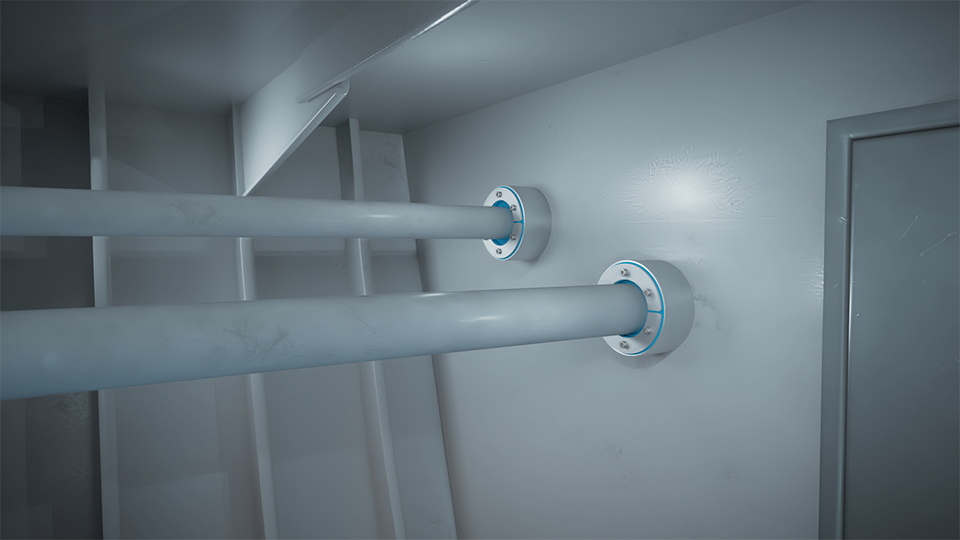

Roxtec RS seal – for easy and fast installation of pipe penetrations

There is, for example, the smart Roxtec RS seal for use with single pipes in metal sleeves or existing holes. It is a sealing solution that helps you ensure safety, cost-efficiency and productivity without any downtime, costs or risks related to welding. The installation only requires work from one side of the section. It can be used with any kind of metal pipe onboard to ensure certified protection against fire, gas and water. The entry seal has two halves with removable layers making it adaptable to pipes of different sizes. The Roxtec RS range covers services with an outer diameter of 25 to 647 mm. The design of the transit makes it easy to install around existing pipes. The Roxtec RS seal is Class A fire rated according to the IMO 2010 FTP Code. It is certified for up to 2.67 bar catastrophic gas pressure and 4 bar catastrophic water pressure.

Multi-cable transits with built-in spare capacity

When it comes to designing or installing fire rated, watertight and gas-tight cable penetration seals for the engine control room, you can include Roxtec multi-cable transits in your shipyard standard. Roxtec provides certified mechanical seals, such as Roxtec S transits, that help you manage high cable density and secure tightness also with braided and armored cables. The seals are easy to install under cabinets and ideal for ensuring the required distance between deck and floor. They enable routing of multiple cables in one opening and are ready for use directly after installation. The seals can be prepared with spare sealing modules to provide built-in spare capacity for changes during construction. When all sealing modules are already in place, there is no need for drilling new holes or purchasing any extra modules. The sealing modules adapt to cables and pipes of different sizes which helps installers handle any surprises regarding service sizes. You can inspect and verify the installation quality visually. To summarize, Roxtec multi-cable and pipe transits help shipyards increase speed of installation, reduce cost and enable better utilization of space onboard.

Technical support onsite during engine room construction

Besides efficient cable and pipe sealing solutions for the engine and engine control room that meet all current and future requirements, Roxtec provides local technical support online and onsite. It includes installation training in the field and practical installation tools. The complete sealing solution provider Roxtec has also developed a suite of software that simplifies design, engineering and the installation process as well as the set up and maintenance of a mandatory class compliant cable transit seal systems register. The Roxtec Transit Build™ software in the suite is especially developed for shipyards searching for efficiency through digitalization. It helps you monitor the installation work during engine room construction, meet the class requirements regarding watertight cable transits and hand over an approved register and inspection report to the owner.

Roxtec has extensive resources for product development, pre-certification testing and preparation of customized sealing solutions to help shipyards overcome specific challenges in, for example, the engine room. Roxtec often performs special customer requested tests to fulfill all possible demands. With global coverage, strong local presence, and regional distribution centers and local warehouses strategically located, Roxtec can always offer technical support and swift deliveries.