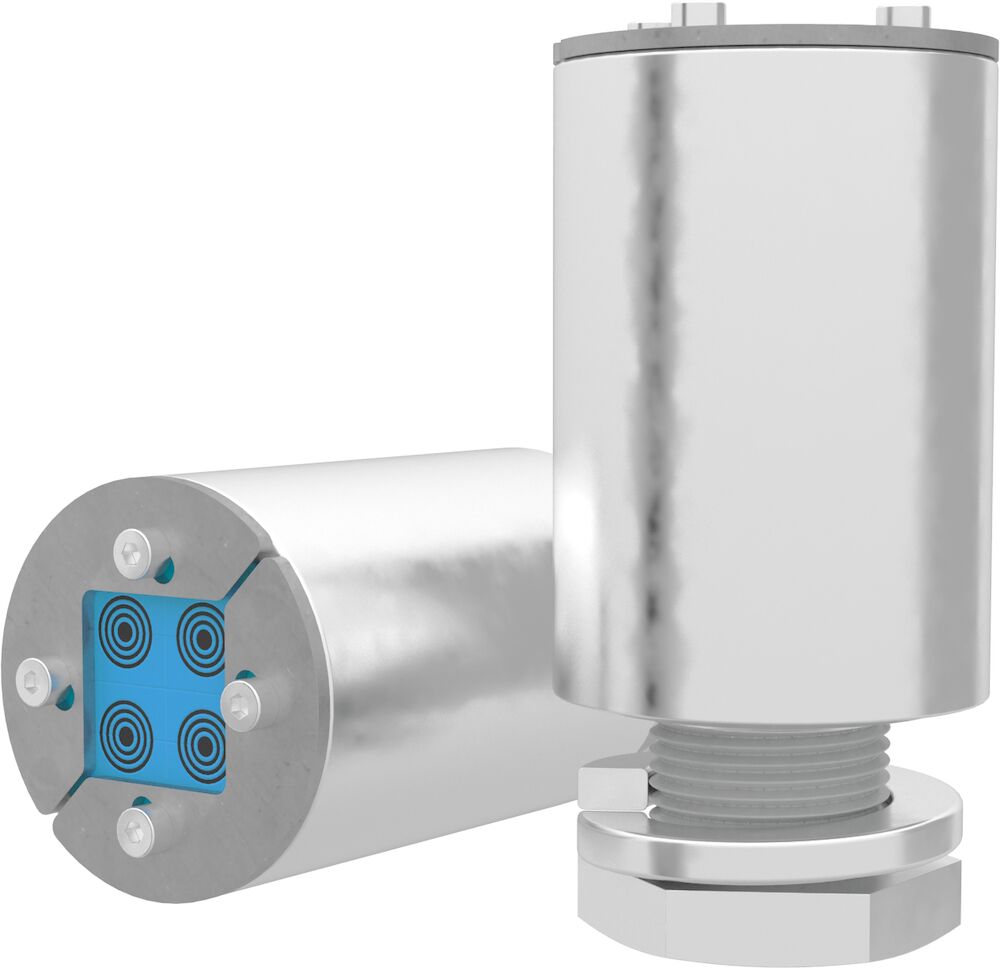

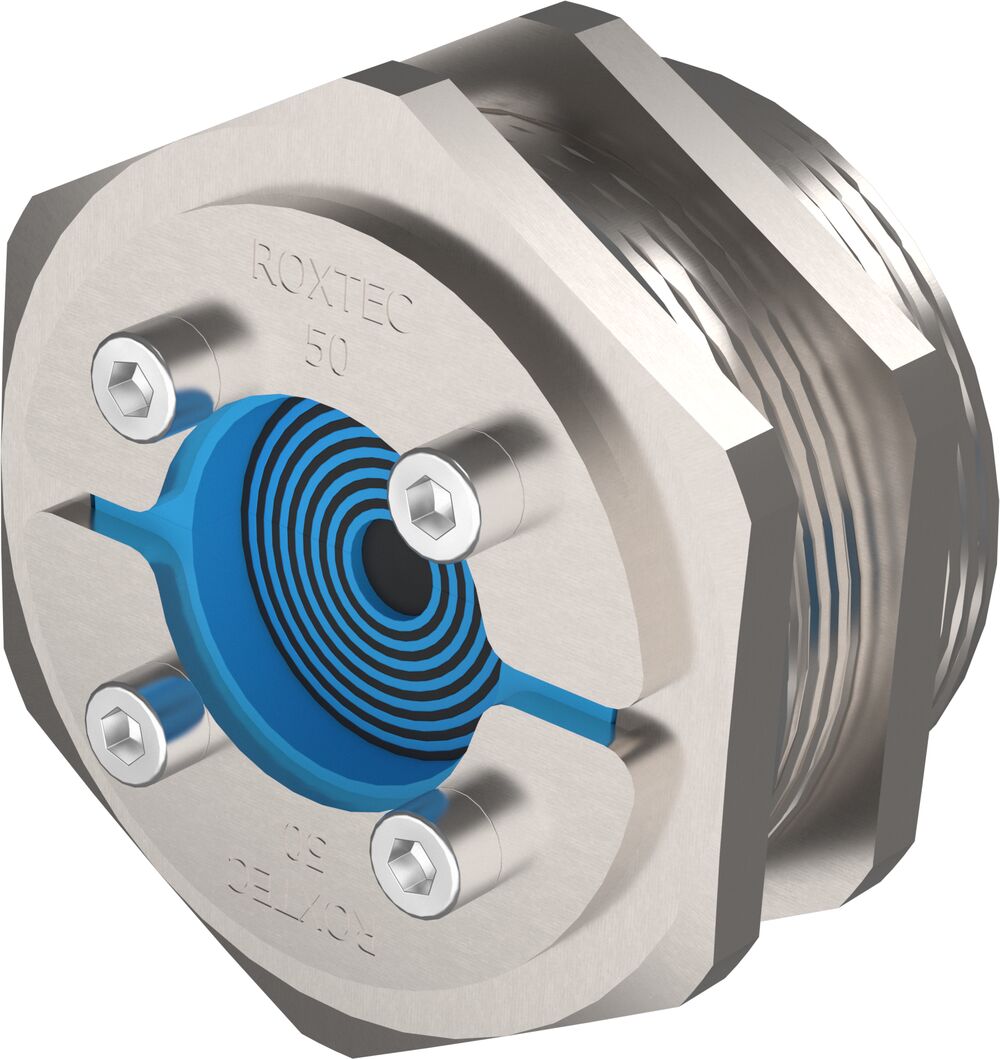

Roxtec cable and pipe transits are approved for offshore safety requirements. The seals are beneficial for end-users, but also for original equipment manufacturers. Manufacture cabinets, machines and equipment without knowing the exact cable or pipe configurations in advance.

Why use Roxtec?

- Watertight

- Gas-tight

- Dust-tight

- Explosion protection

- EMI protection

Superior simplicity

- One opening for dozens of pre-terminated cables

- Flexibility for cables and pipes of different sizes

- Built-in spare capacity for last-minute changes