Schalker Eisenhütte Maschinenfabrik GmbH in Gelsenkirchen, Germany, selects Roxtec seals for its mining locomotives.

In cooperation with mine owner LKAB, Schalke has developed a unique trolley wire locomotive for iron ore mines in northern Sweden. The locomotive operates 1,365 meters underground, and as the environment is extremely challenging when it comes to humidity and dust, the designers have chosen to secure all crucial cable entries onboard with Roxtec seals. In order to maintain a reliable and continuous operation, it is a must to protect sensitive equipment from iron dust.

The best sealing solution

Schalke has tried many sealing products in different projects during the years. The company's engineers have found out that "there is no better way to seal efficiently than with Roxtec".

In this case, there is hardly any space left to work on in the locomotive, but the cable entries still have to be tight. Roxtec provides a reliable solution demanding very little space.

Useful flexibility

The locomotives are built in Germany and divided into parts before shipping. Upon arrival in Sweden, they are remounted underground. That is why it is practical to use a cable sealing solution that can be opened and resealed.

Better than cable glands

Kai Krolik of Schalke installed the seals. He learned quickly and was able to benefit from the flexibility of the system and route many cables through each opening.

"When we used cable glands we needed more space for tools. It is faster and easier to install Roxtec."

Roxtec is easier than glands.

Why use Roxtec?

- Area efficient

- Quick and easy to install

- Can be opened and resealed

- Excellent dust-tightness

- Reliable humidity barrier

Project facts

Project description

Design and manufacturing of heavy production locomotive for the mining industry

Owner

LKAB (Luossavaara-Kiirunavaara Aktiebolag)

Design, engineering, manufacturing and electrical installations

Schalke (Schalker Eisenhütte Maschinenfabrik GmbH)

Applications

Sealing of electrical control and power cables throughout the locomotive

Sealing requirements

IP 66/67, EN-45545 and dust protection

Roxtec products

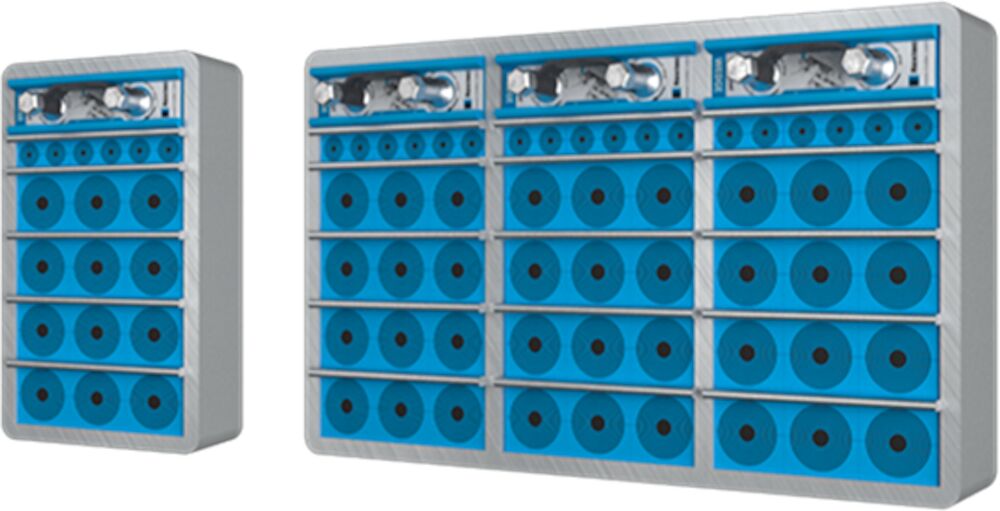

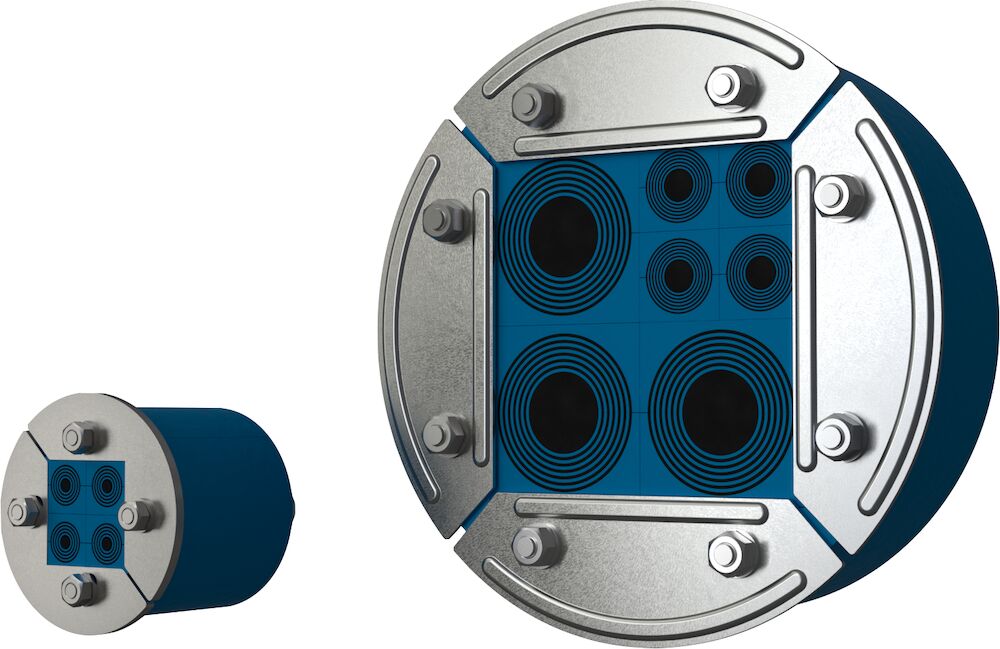

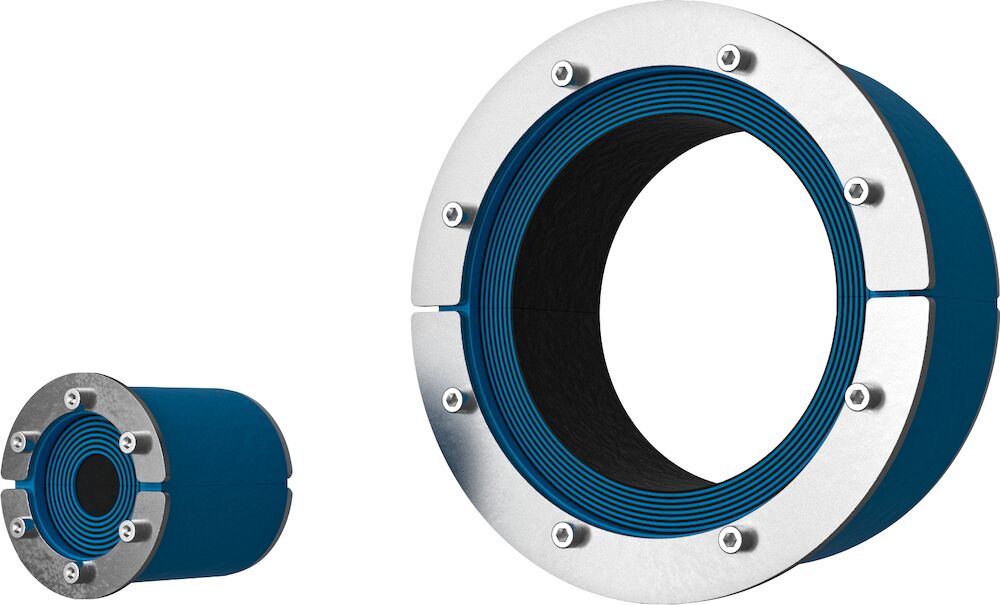

These sealing solutions were used in the project: