“I was not aware of Roxtec non-weld solutions and had not realized how much time and money we could save. We were welding when we really did not have to weld”, says Bobby Conrad, Maritime Production Branch Manager of the GBS Group.

GBS Group, located in Virginia Beach, USA, performs electrical installations worldwide. When working on the USNS Bob Hope in a shipyard on the US west coast, they had to run nine power, network, and data cables through the deck for a new information system. The initial suggestion of using fire caulk to seal the penetration was rejected by ABS, American Bureau of Shipping. When GBS suggested using Roxtec, ABS agreed Roxtec would be in line with meeting the necessary requirements for the project.

Great cost and time savings

The suggestion to use Roxtec would turn into previously unknown time and cost savings for GBS. Instead of using a fire caulk solution requiring welding of a 4-inch pipe, GBS sealed the penetration with an A60 rated Roxtec R transit in a Roxtec sleeve.

“We saved thousands of dollars on one penetration,” says Bobby Conrad. “And the installation was a piece of cake. It took us less than an hour to drill a hole through the 1/4" deck, then we installed the gasket in five minutes and spent another 20 minutes to tighten the bolts.”

In comparison to welding

There are many steps and costs connected to welding, such as hiring a marine chemist, fire watch personnel and a welder for several hours, even if the actual work only takes ten minutes. There is of course a need for a welding machine and equipment, and for hauling it all down into the ship. In addition, everyone hired must be equipped with personal protective equipment and the area needs to be cleaned of any explosive material. Scheduling for having everyone available at the same time can be a challenge, as well as following the hot work permit check list and making sure all steps are signed off.

“I do not think Roxtec can comprehend the difference in price by using this type of frame, especially since it is A60 rated. It would have cost me between $3,000 and $5,000 to have a deck sleeve welded in and put fire stop in it,” says Bobby Conrad.

Roxtec seals meet the fire ratings, protect against water, and simplify changes. Thereby, they provide long-term protection as well as possibilities for further savings.

We save thousands of dollars by using Roxtec non-weld seals.

Why use Roxtec?

- Fire-proof

- Watertight

- Rated and certified

- Simplifies upgrades

- No need for welding

Project facts

Project description

Addition of equipment and cables onboard USNS Bob Hope

Involved companies

MSC, Maritime Sealift Command – owner, GBS Group – contractor and installer

Applications

Sealing of cable penetration in deck

Sealing requirements

Fire rated, Watertight

Roxtec products

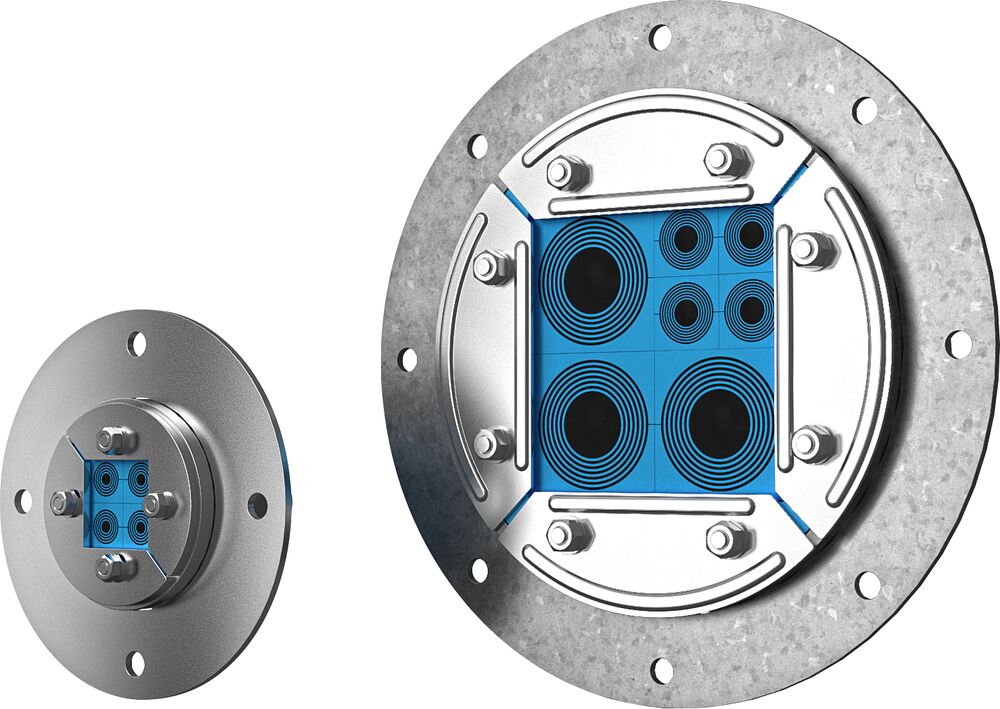

Roxtec R transit with SLFR sleeve

Roxtec Products

Roxtec R transit with SLF R

Round transit for sealing around multiple cables and pipes in a limited area.

Includes sleeve for bolting