When modernizing the corvettes Manabí and Loja for the Ecuadorian Navy, shipyard ASTINAVE specified Roxtec cable transits between compartments instead of cable glands. The seals are used to stow cables – and to protect against fire, gas and water.

The change to Roxtec multi-cable transits solved three issues. Roxtec seals allow more cables in each opening than cable glands and provide a solution for managing all the cables. They also ensure a better barrier against water, fire, dust and noise between compartments.

Long-lasting solution

The challenge when upgrading was to efficiently stow and align all the armored, shielded and concentric cables. Selecting Roxtec sealing modules is wise: the rubber material is resistant to multiple risk factors and provide optional spare capacity for future upgrades.

“In order to keep the compartments watertight and free of dust, smoke, gas and noise, we applied different types of modules for one or more cables. The product offered by Roxtec is also very useful to keep all cables stowed and to separate electrical wiring which, due to its nature, cannot be mixed with the rest,” says Fabián Ayala Terán, engineer of ASTINAVE.

The Roxtec solution for sealing cables between compartments is very effective.

Saving a lot of time

Another benefit is the easy mounting of transit frames and modules. Roxtec experts inform onsite and provide practical installation tools. The installers rapidly gained knowledge and were able to perform the installations correctly – and to finalize the work before schedule.

“The trainings issued by Roxtec’s personnel were very effective since they helped the project staff to function more quickly and efficiently,” says Fabián Ayala Terán.

Why use Roxtec?

- Certified protection

- Cable management

- Area efficiency

- Quick and easy installation

- Spare capacity for upgrades

Project facts

Project description

Modernization of corvettes for the Ecuadorian Navy

Involved companies

Ecuadorian Navy – owner,

ASTINAVE – shipbuilder,

Group 300 – electrical installer,

Sudamericana de Energía

Applications

Cable sealing between compartments

Sealing requirements

Watertight,

Gas-tight,

Fire-proof,

Dust-tight,

Noise reduction,

Cable Management

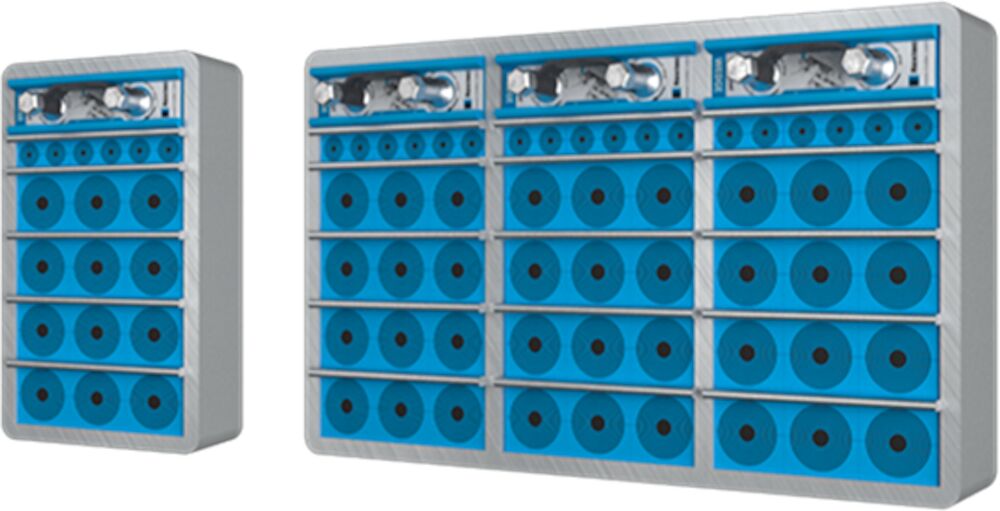

Roxtec products

These sealing solutions were used in the project:

Roxtec S transit

Transit for welding to the structure.

For welding into precise aperture